-

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software hereThank you for being a part of our community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuel pump relay won’t stay engaged

- Thread starter ryanfay

- Start date

ryanfay

more bounce to the ounce

- Joined

- Dec 1, 2010

- Location

- Brisbane, CA

I suppose I could give it a try tomorrowPut a 5k-10k resistor across vr+ and vr-,

Set tooth zero to 84° and run it in wasted spark.

ryanfay

more bounce to the ounce

- Joined

- Dec 1, 2010

- Location

- Brisbane, CA

I wouldn’t miss itYes. It’s dumb.

ryanfay

more bounce to the ounce

- Joined

- Dec 1, 2010

- Location

- Brisbane, CA

So I've been perseverating on this issue maybe am unhealthy amount. I wired it to the cps and put in the settings that you said Robert. The crank signal seems more consistent but it still drops sync over and over.

This is the cps signal when the ecu is actually on. The Rx and Tx wires (and com ground) were all wires that were mixed in the harness that I had to troubleshoot and rewire. Maybe it's something with that? My patch job is still the one that I did when I trouble shot it. Perhaps if I did an actual good wire job this could correct this???

This is the cps signal when the ecu is actually on. The Rx and Tx wires (and com ground) were all wires that were mixed in the harness that I had to troubleshoot and rewire. Maybe it's something with that? My patch job is still the one that I did when I trouble shot it. Perhaps if I did an actual good wire job this could correct this???

dl242gt

The world of the smiling Dogo

- Joined

- Jun 21, 2002

- Location

- S NJ, a suburb of Phila.

Shielded wire helps the crank signal be less noisy.

ryanfay

more bounce to the ounce

- Joined

- Dec 1, 2010

- Location

- Brisbane, CA

Heres a screen shot of the tooth log with the 60-2 flywheel vr wired up. I figured out the harness has a 1k ohm resistor somewhere in the harness shunting the two vr leads. I'm not sure where it is in the harness but the multimeter says it's there. The car catches more readily with it on the vr than the cas. It just wont actually run because theres still an apparent sync issue where the fuel cuts out. The sync error counter is still very low, often zero. The errors all seem to happen the very first pulses on cranking. I also rewired the serial comm stuff, not sure if that had any effect on the current issue though.

bobxyz

Board Member

- Joined

- Aug 29, 2014

- Location

- Boulder CO

Try changing the ignition Input Capture Edge from rising to falling, or vice versa, and see if it does any better.

It's not unusual for the lost sync counter to count 1 or 2 counts on initial startup.

It's not unusual for the lost sync counter to count 1 or 2 counts on initial startup.

ryanfay

more bounce to the ounce

- Joined

- Dec 1, 2010

- Location

- Brisbane, CA

One setting does work better than the other, can’t remember which.Try changing the ignition Input Capture Edge from rising to falling, or vice versa, and see if it does any better.

It's not unusual for the lost sync counter to count 1 or 2 counts on initial startup.

Culberro came over last night and showed me some things, much appreciated. There were a number of things that were tweaked. The 1k resistor was located in the loom and hacked out. So far, the sync loss problem isn’t gone, but is getting better. Today after work, I’ll try the bigger (7.5k) shunt resistor, clean up some more wiring, try another serial cable, whatever else comes to mind.

It did run last night for a solid 30 seconds, until the sync gremlin snarled.

bobxyz

Board Member

- Joined

- Aug 29, 2014

- Location

- Boulder CO

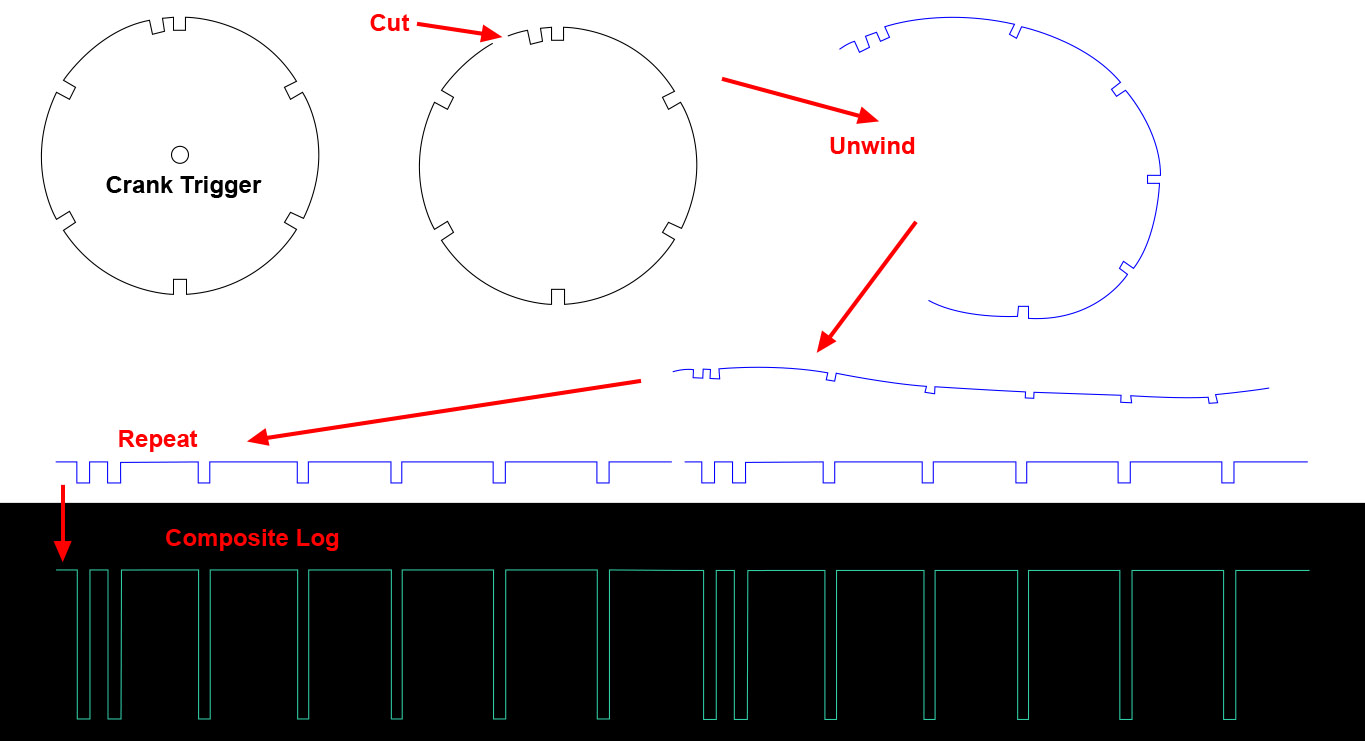

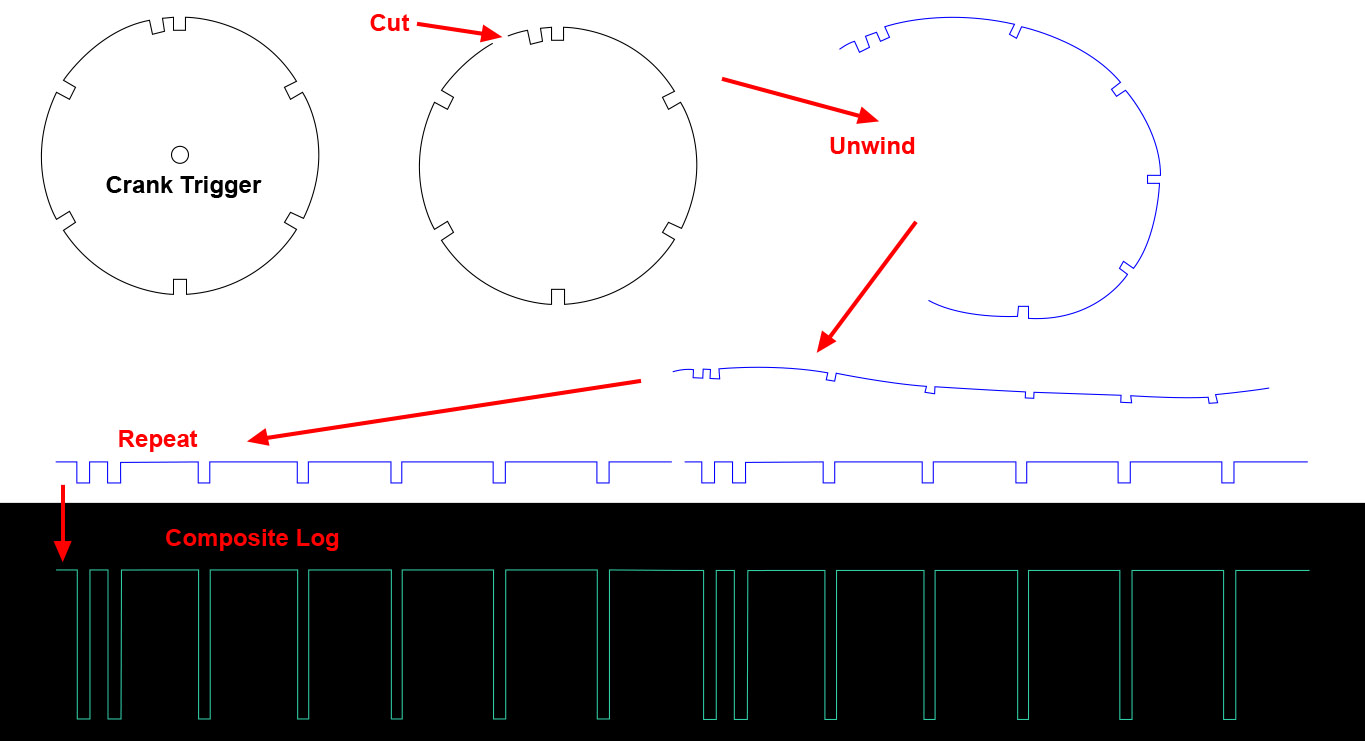

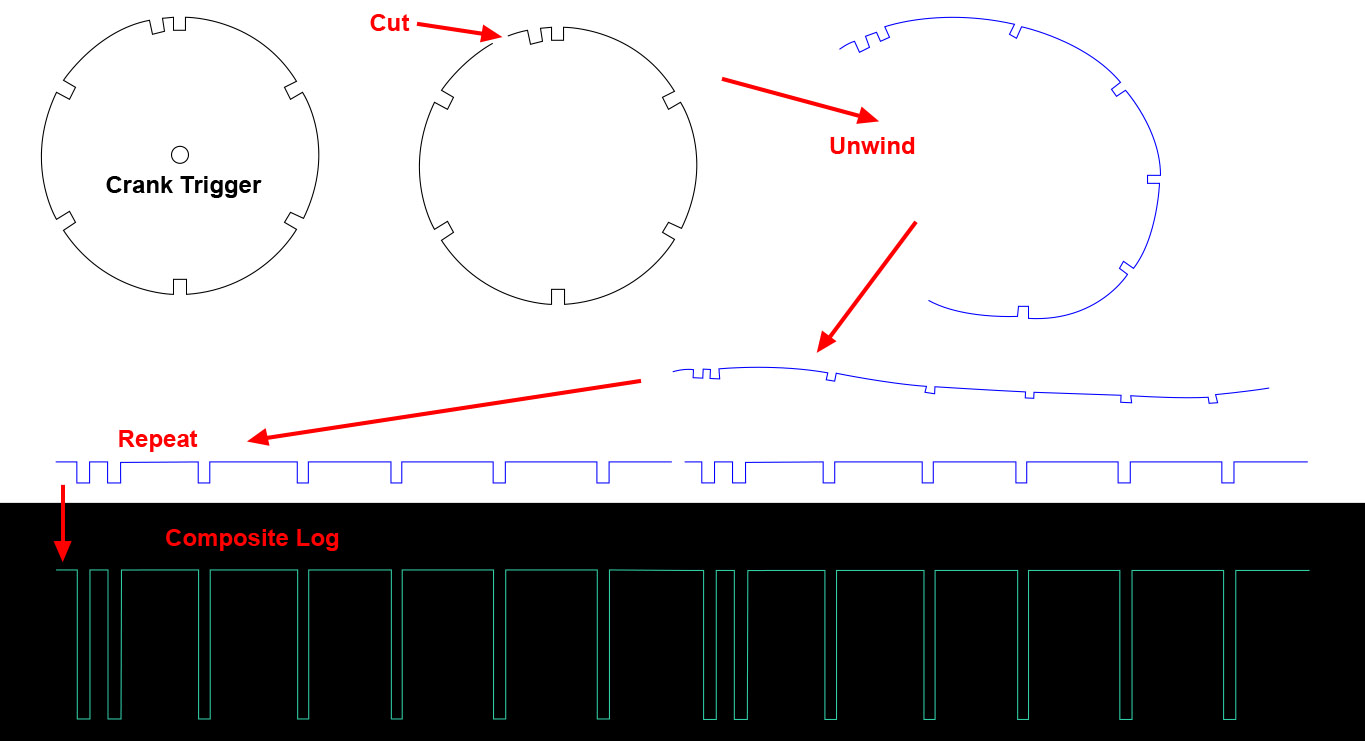

Try another composite tooth log without the 1K - you want to see a single extra long (3 tooth long) spike in the graph for the missing tooth, not 2 side-by-side long spikes.

The 5K or 7.5K shunt resistor improves high-RPM sync loss, but makes crank+starting a bit harder.

The 5K or 7.5K shunt resistor improves high-RPM sync loss, but makes crank+starting a bit harder.

Don't forget some fresh plugs!One setting does work better than the other, can’t remember which.

Culberro came over last night and showed me some things, much appreciated. There were a number of things that were tweaked. The 1k resistor was located in the loom and hacked out. So far, the sync loss problem isn’t gone, but is getting better. Today after work, I’ll try the bigger (7.5k) shunt resistor, clean up some more wiring, try another serial cable, whatever else comes to mind.

It did run last night for a solid 30 seconds, until the sync gremlin snarled.

Another composite log would be a good idea! I haven't had any issues with the 7.5k resistor when cranking on a number of installs now. It seems to be the sweet spot while still allowing revs to 8500.Try another composite tooth log without the 1K - you want to see a single extra long (3 tooth long) spike in the graph for the missing tooth, not 2 side-by-side long spikes.

The 5K or 7.5K shunt resistor improves high-RPM sync loss, but makes crank+starting a bit harder.

The car went from ~ 1 sync loss every 2-3 seconds to just 2 while farting around trying to get it started once the 1k resistor was removed.

There was an odd issue with either the ECU , usb-serial adapter, or the usb port where it would drop out and have a "memory issue" error pop up when adjusting tables. That's something I've never seen before, so I suggested Ryan try out a new serial adapter and maybe try reflashing the firmware again since the car would die if I selected a cell when live tuning. I ran into the selecting cell and dying/stumbling issue a while back and a firmware update was the fix.

ryanfay

more bounce to the ounce

- Joined

- Dec 1, 2010

- Location

- Brisbane, CA

Here's the tooth log showing the better cps signal.

This comp shows a bunch of misses all at once. I often get this: a bunch a few cycles in.

In all the suck this 'pnp' harness has provided, I am half wondering if the cps wiring is shielded...

I updated the firmware, tried other serial cables, with and without various resistors, changed the plugs, I tried Roberts tune even. I still have sync issues I'm about to lose it man. I don't know what else to try. This sucks. I'm going to call yoshifab tomorrow and see if he has any ideas.

Last edited:

In all the suck this 'pnp' harness has provided, I am half wondering if the cps wiring is shielded...

That’s easy enough to check. I honestly don’t remember seeing a shielded wire or an added drain.

On the CPS connector there should be a ground/drain wire (pin 3?) that ends up being connected to a sensor ground pin. You know what shielded pair wire looks like, so I don’t need to explain that.

From the ecu side you should be able to see it easily enough since it’s all out in the open on your car right now.

ryanfay

more bounce to the ounce

- Joined

- Dec 1, 2010

- Location

- Brisbane, CA

The wires are not shielded. So to clarify with the manufacturer of this pnp harness: is this circuit supposed to be done in shielded wire?That’s easy enough to check. I honestly don’t remember seeing a shielded wire or an added drain.

On the CPS connector there should be a ground/drain wire (pin 3?) that ends up being connected to a sensor ground pin. You know what shielded pair wire looks like, so I don’t need to explain that.

From the ecu side you should be able to see it easily enough since it’s all out in the open on your car right now.

dl242gt

The world of the smiling Dogo

- Joined

- Jun 21, 2002

- Location

- S NJ, a suburb of Phila.

Volvo used a shield for the crank sensor. It would only be proper for another ecu to use the same. BMW used a shielded wire for the VR signal from the distributor with Kjet on my brothers old e21.

bobxyz

Board Member

- Joined

- Aug 29, 2014

- Location

- Boulder CO

The capture edge setting in the new tooth logger log looks good - shows a single 3x long spike. The red spikes are normal after a lost sync -- it shows a red spike for every tooth that it takes to get sync again.

The yoshifab/prancing moose conversion harnesses should have shielded wiring for the crank/cam sensors. Maybe one of them can comment on

a) how the shielding is wired (specifically, what pins / terminals are connected to the shield at each end of the cable), and

b) why these aren't for sale anymore.

www.prancingmoose.com

www.prancingmoose.com

Can you turn on Ignition - NoiseFiltering - NoiseFilterEnable (but leave the other filters off), then do a HighSpeedLogger - CompositeLogger log to try to capture the details of a lost sync.

www.diyautotune.com

www.diyautotune.com

The yoshifab/prancing moose conversion harnesses should have shielded wiring for the crank/cam sensors. Maybe one of them can comment on

a) how the shielding is wired (specifically, what pins / terminals are connected to the shield at each end of the cable), and

b) why these aren't for sale anymore.

Prancingmoose.com, Dave's Volvo Page

For Volvo enthusiasts. Prancing Moose stickers, labels, decals.

Can you turn on Ignition - NoiseFiltering - NoiseFilterEnable (but leave the other filters off), then do a HighSpeedLogger - CompositeLogger log to try to capture the details of a lost sync.

Using the Tooth Logger and Composite Logger

Use TunerStudio's tooth logger and composite logger to troubleshoot problems with the crankshaft position sensor or camshaft position sensor.

Last edited:

ryanfay

more bounce to the ounce

- Joined

- Dec 1, 2010

- Location

- Brisbane, CA

The harness isn’t shielded on the vr at all. I sent pics to yoshifab and wish I could post his response here man but my scruples prevent me. It’s classic. After that he won’t respond so I have no idea what the thought process was.

Not only was it unshielded but there were multiple legs of the vr circuit running to other connectors for different configurations with god knows what resistors and whatever else in the connectors.

I went to hd and got two strand shielded wire and wired it in like Robert Culberson told me but I still have sync loss. Not all as bad but still one every few cycles.

Not only was it unshielded but there were multiple legs of the vr circuit running to other connectors for different configurations with god knows what resistors and whatever else in the connectors.

I went to hd and got two strand shielded wire and wired it in like Robert Culberson told me but I still have sync loss. Not all as bad but still one every few cycles.

I will definitely post a screen shot of this. Thank you for your help Bob. I appreciate itThe capture edge setting in the new tooth logger log looks good - shows a single 3x long spike. The red spikes are normal after a lost sync -- it shows a red spike for every tooth that it takes to get sync again.

The yoshifab/prancing moose conversion harnesses should have shielded wiring for the crank/cam sensors. Maybe one of them can comment on

a) how the shielding is wired (specifically, what pins / terminals are connected to the shield at each end of the cable), and

b) why these aren't for sale anymore.

Prancingmoose.com, Dave's Volvo Page

For Volvo enthusiasts. Prancing Moose stickers, labels, decals.www.prancingmoose.com

Can you turn on Ignition - NoiseFiltering - NoiseFilterEnable (but leave the other filters off), then do a HighSpeedLogger - CompositeLogger log to try to capture the details of a lost sync.

Using the Tooth Logger and Composite Logger

Use TunerStudio's tooth logger and composite logger to troubleshoot problems with the crankshaft position sensor or camshaft position sensor.www.diyautotune.com

bobxyz

Board Member

- Joined

- Aug 29, 2014

- Location

- Boulder CO

Please attach the log instead of just a screenshot. You may need to .zip it first (I forget what file types are allowed for attachments). Including a normal tunerstudio log would be good too.

Toybox

mostly lurking

- Joined

- Dec 31, 2018

- Location

- SF Bay Area

The harness isn’t shielded on the vr at all. [...] Not only was it unshielded but there were multiple legs of the vr circuit running to other connectors for different configurations with god knows what resistors and whatever else in the connectors.

Maybe it's time to start over. You're pretty good with both tech and diagrams... You could probably rebuild the entire stinkin' harness faster than you're ever going to obtain satisfaction. Heck, you could probably even pay someone to do that, for less than the current aggravation. (I ran into the same problem after a plumber left, then a solder joint leaked, then another one leaked... decided I didn't want that guy back, tore apart most of it and re-sweated myself. Found two places where the straight pieces were too short to bottom in the cup but he didn't feel like wasting time or material to cut new pieces properly. Duh.)

I sent pics to yoshifab and wish I could post his response here man but my scruples prevent me. It’s classic. After that he won’t respond so I have no idea what the thought process was.

Thank you for your scruples.

Very strange... I've not heard any bad words about yoshifab until this. A search (TB, Brickboard, Swedespeed, MVS, Duck Duck Go) reveals nothing amiss.

Even more strange:

from yoshifab About Us said:In August 2008, I hired my first employee, Nick Salyer. Nick is a guy I met through DSMs who is also a skilled fabricator and wiring guru. When it comes to things intricate and electronic, there is nobody I rather have working on it.

So...... even if he buys the harness from elsewhere... or perhaps especially if... wouldn't he want his guru to go through it first, before selling it?

wikipedia said:Lemon laws are laws that provide a remedy for purchasers of cars and other consumer goods in order to compensate for products that repeatedly fail to meet standards of quality and performance. Although many types of products can be defective, the term "lemon" is mostly used to describe defective motor vehicles, such as cars, trucks, and motorcycles.

Lemon law protection arises under state law, with every U.S. state and the District of Columbia having its own lemon law.[1] Although the exact criteria vary by state, new vehicle lemon laws require that an auto manufacturer repurchase a vehicle that has a significant defect that the manufacturer is unable to repair within a reasonable amount of time.[2] Lemon laws consider the nature of the problem with the vehicle, the number of days that the vehicle is unavailable to the consumer for service of the same mechanical issue, and the number of repair attempts made. If repairs cannot be completed within the total number of days described in the state statute, the manufacturer becomes obligated to buy back the defective vehicle. Contrary to popular belief, the dealership has no obligation to buy back the vehicle, because the dealership does not warrant the vehicle, the manufacturer does.

The lemon law might not apply 100%... but after all this time, and given the possibility of bad press, I'd think yoshifab would be highly interested in making something in your life better.

ryanfay

more bounce to the ounce

- Joined

- Dec 1, 2010

- Location

- Brisbane, CA

I agree this sucks. I’ve completely lost faith in him as a vendor now that I see how he doesn’t stand by his products. I always thought he was great until I got this dud. The weird thing is I’m sure a lot of people bought these through him and prancing moose. He told me that they were pretty much all bad. At least when JVAB’s flywheels were wrong he refunded everyone. Josh said he would not refund me that I need to wait for a replacement harness that may or may not come. He said the guy (who he wouldn’t name) that made the harnesses is overseas and is a raging alcoholic. So it’s this drunk guys fault not his. That it’s unfair to him (Josh) because now he has to deal with all these angry customers for Yoshi and prancing moose. I’m supposed to feel bad that he never checked any of the harnesses were wired right or even try one on a car. One would think he’d want to chime in here or at least be more willing to help me get it going but no. He’s too busy backpedaling playing cya and probably just wants to forget about this whole venture that didn’t work too good for him.Maybe it's time to start over. You're pretty good with both tech and diagrams... You could probably rebuild the entire stinkin' harness faster than you're ever going to obtain satisfaction. Heck, you could probably even pay someone to do that, for less than the current aggravation. (I ran into the same problem after a plumber left, then a solder joint leaked, then another one leaked... decided I didn't want that guy back, tore apart most of it and re-sweated myself. Found two places where the straight pieces were too short to bottom in the cup but he didn't feel like wasting time or material to cut new pieces properly. Duh.)

Thank you for your scruples.I admit that you've made me kinda curious... but in public ain't right unless ya give a person a chance to make good. (Which it seems like you have, at least to some degree... but good grief, you've been struggling with this a long time.)

Very strange... I've not heard any bad words about yoshifab until this. A search (TB, Brickboard, Swedespeed, MVS, Duck Duck Go) reveals nothing amiss.

Even more strange:

So...... even if he buys the harness from elsewhere... or perhaps especially if... wouldn't he want his guru to go through it first, before selling it?

The lemon law might not apply 100%... but after all this time, and given the possibility of bad press, I'd think yoshifab would be highly interested in making something in your life better.

I don’t want to make this a rant about a shit product any more than it already is. At this point I just want to make my car run. The trouble is: I have to look and deal with this pos to do so. And it’s a thoroughly miswired harness.

Toybox

mostly lurking

- Joined

- Dec 31, 2018

- Location

- SF Bay Area

And it’s a thoroughly miswired harness.

Is there a simulator or a test box... or is it worth making one? Something that serves the same function as a network cable analyzer, but for this particular one-off piece of harness. Ya know, plug in every connector and if you get 37 green LEDs lit, you know you're good...

My theoretical musing describes a piece of test gear that the mfr should have used for QC before shipping product.