Alex Buchka

8 cylinders

- Joined

- Apr 8, 2004

- Location

- Los Angeles

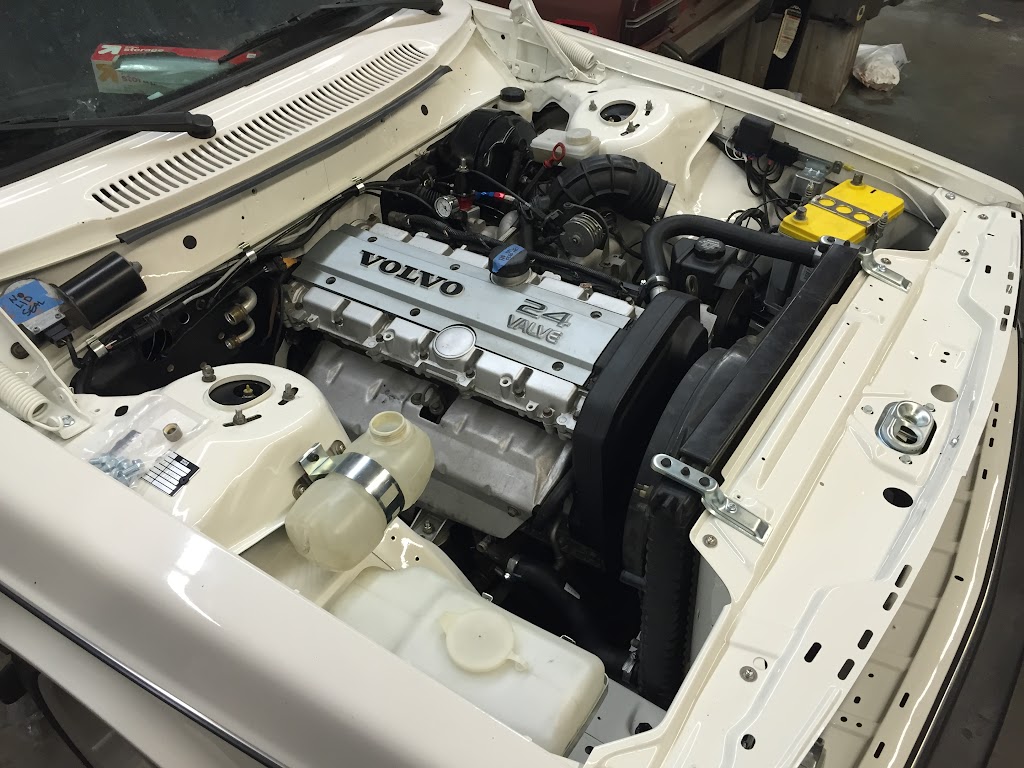

Karl and I made some really good progress yesterday. Engine bay wiring is now 95% complete and looks really tidy, engine and trans are installed, and we started bolting on some ancillary stuff in the engine bay. Still lots of wiring to do inside the car but it feels really good to have the engine and trans in for the last time.

Made a new battery hold-down for the optima out of some stainless sheet and two t-bolt clamps.

Terminated the engine harness with a 55-contact barrel connector. The receptacle side will go in the old speedo cable hole.

Dropping in the engine.

Starting to look more like an engine bay now.

The shifter lines up perfectly and has pretty reasonable throws, really happy with how it turned out.

Made a new battery hold-down for the optima out of some stainless sheet and two t-bolt clamps.

Terminated the engine harness with a 55-contact barrel connector. The receptacle side will go in the old speedo cable hole.

Dropping in the engine.

Starting to look more like an engine bay now.

The shifter lines up perfectly and has pretty reasonable throws, really happy with how it turned out.