wennstroma

Active member

- Joined

- Apr 25, 2006

- Location

- Idaho

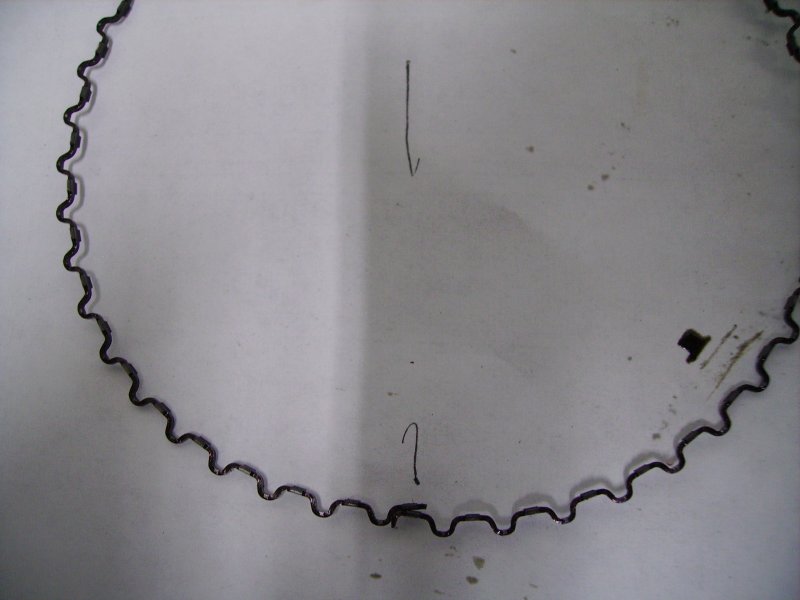

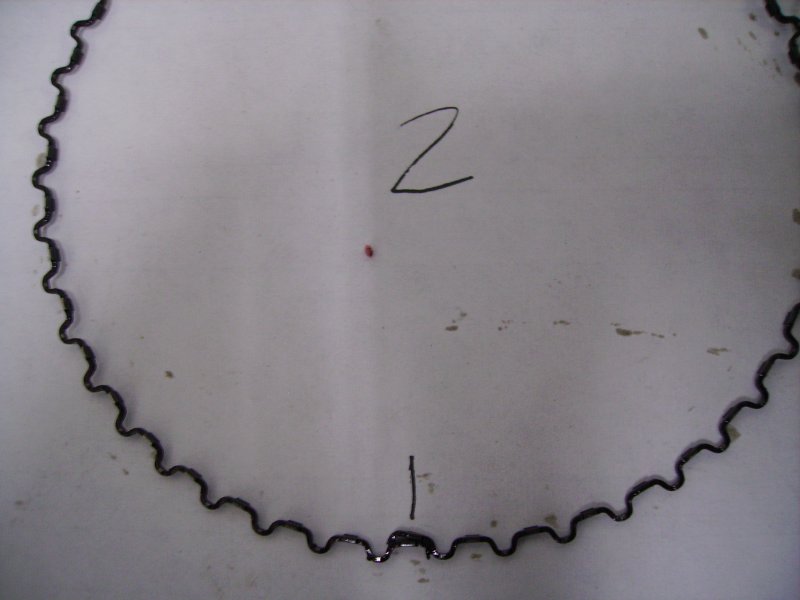

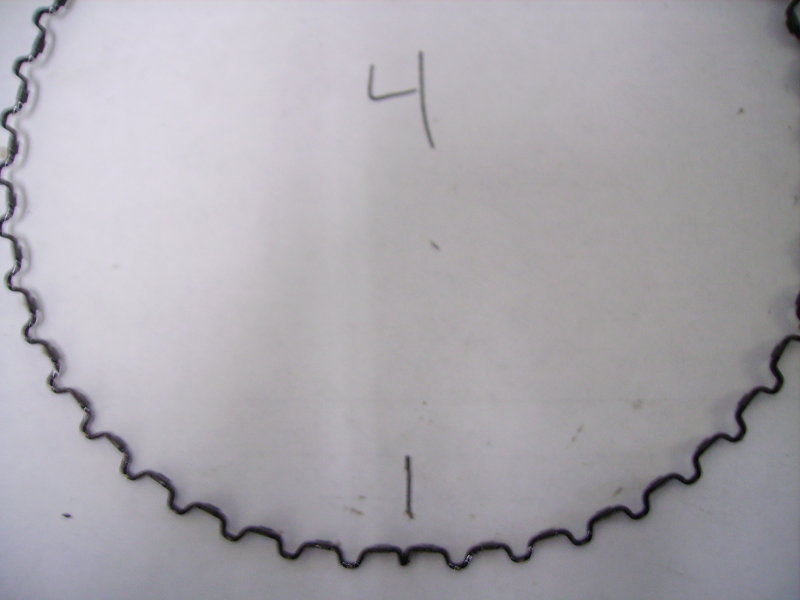

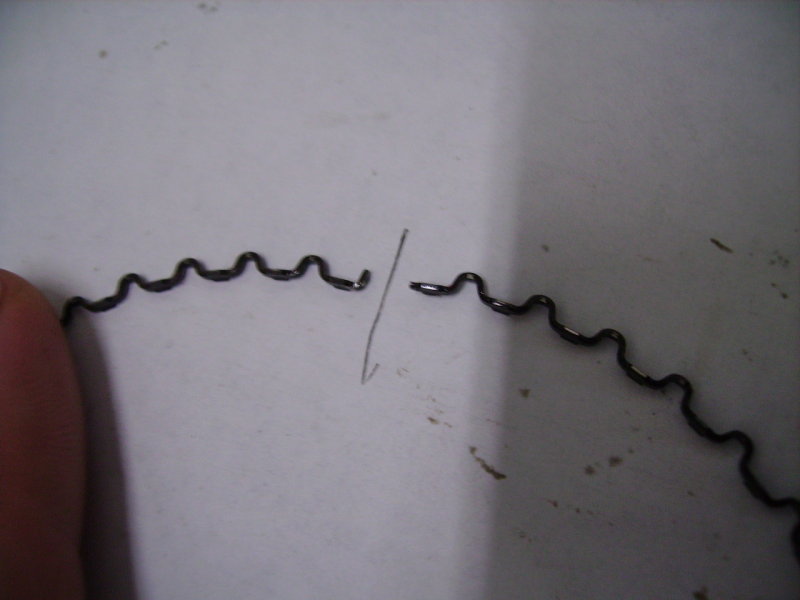

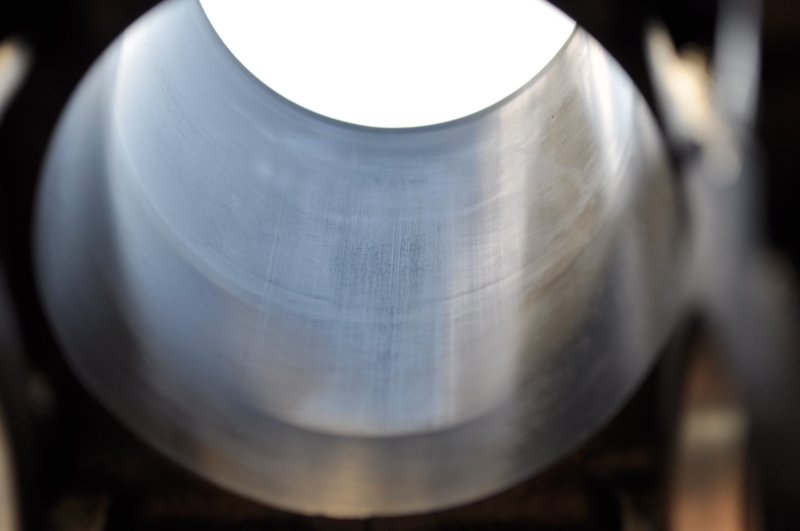

I took the rings off this morning and the expanders seem to be incorrectly made/finished  .

.

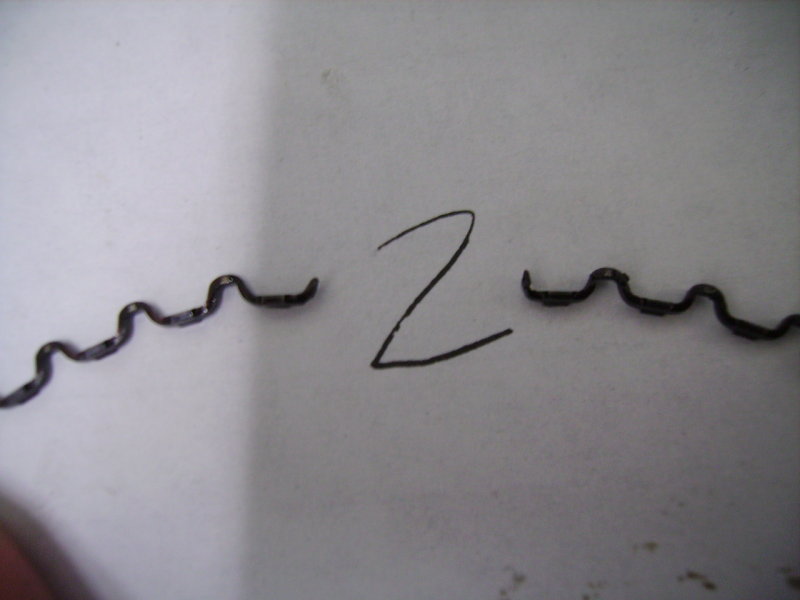

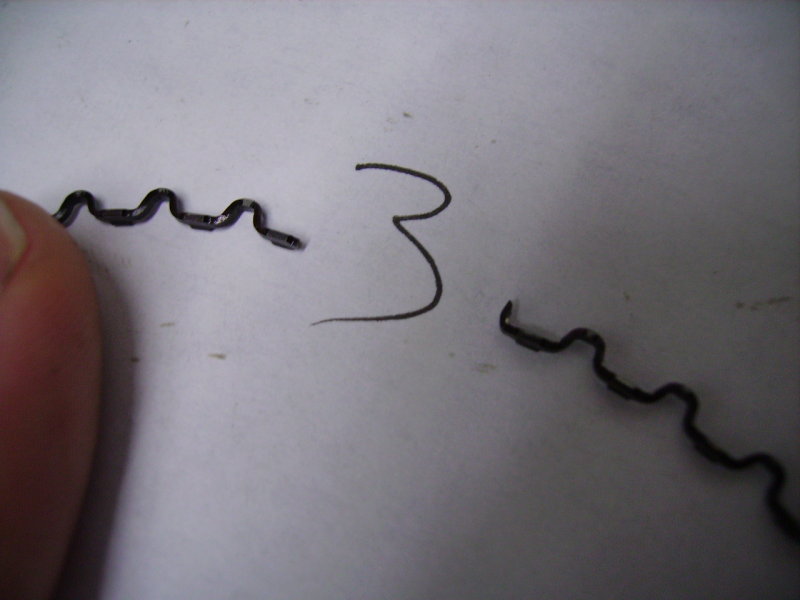

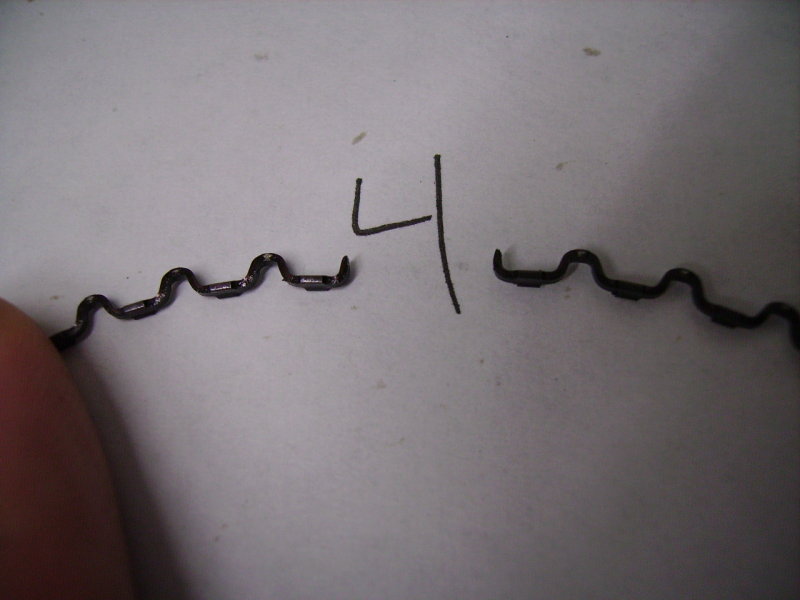

On 1-3, the ends of the rings do not butt correctly. One side will be flat and the other stepped up, so when you put it on the piston they overlap. On #4 they are both barely stepped up and meet normally but still do not provide very much tension.

I will post pictures tonight.

I'm not really impressed with cp's quality, when I got the pistons all of the oil drain holes had burrs that I had to remove. And now this.

.

.On 1-3, the ends of the rings do not butt correctly. One side will be flat and the other stepped up, so when you put it on the piston they overlap. On #4 they are both barely stepped up and meet normally but still do not provide very much tension.

I will post pictures tonight.

I'm not really impressed with cp's quality, when I got the pistons all of the oil drain holes had burrs that I had to remove. And now this.