-

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software hereThank you for being a part of our community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Modifying intake ports with epoxy, experiences thereof

- Thread starter Dammit

- Start date

hessam69

Well-known member

- Joined

- Jun 19, 2009

- Location

- Sydney, Australia

- Joined

- Jul 30, 2002

- Location

- Rockville, MD

Njal has played with this, certain epoxies can work in the head... others are just good enough for flow bench or a few dyno runs.

VB242

I.M. Weasel

- Joined

- Sep 21, 2011

- Location

- Driving the No Malarkey Bus

How beneficial is this on a turbo motor? I can see N/A but the turbo is going to be shoving the air in regardless of port size.

shoestring

Well-known member

- Joined

- Jun 20, 2009

- Location

- Swampscott, 01907

How beneficial is this on a turbo motor? I can see N/A but the turbo is going to be shoving the air in regardless of port size.

Improved flow is improved flow.

Tfrasca

Active member

- Joined

- Apr 20, 2015

- Location

- Ben Lomond, CA

Improved flow is improved flow.

But isn't this trying to improve velocity? Seems like tuning the port for maximum velocity is much more important on an NA engine.

I have no experience with this, just thinking out loud.

Being honest - I don't know, this is for an NA engine that we're turning to 8-8,500 rpm.

Your conjecture makes sense to me though- with a turbo engine you have constant positive pressure, so manifold resonance tuning and velocity is (I would think) not so important as it is to an NA engine.

Your conjecture makes sense to me though- with a turbo engine you have constant positive pressure, so manifold resonance tuning and velocity is (I would think) not so important as it is to an NA engine.

shoestring

Well-known member

- Joined

- Jun 20, 2009

- Location

- Swampscott, 01907

Disclaimer: none of the following should be taken as an absolute.

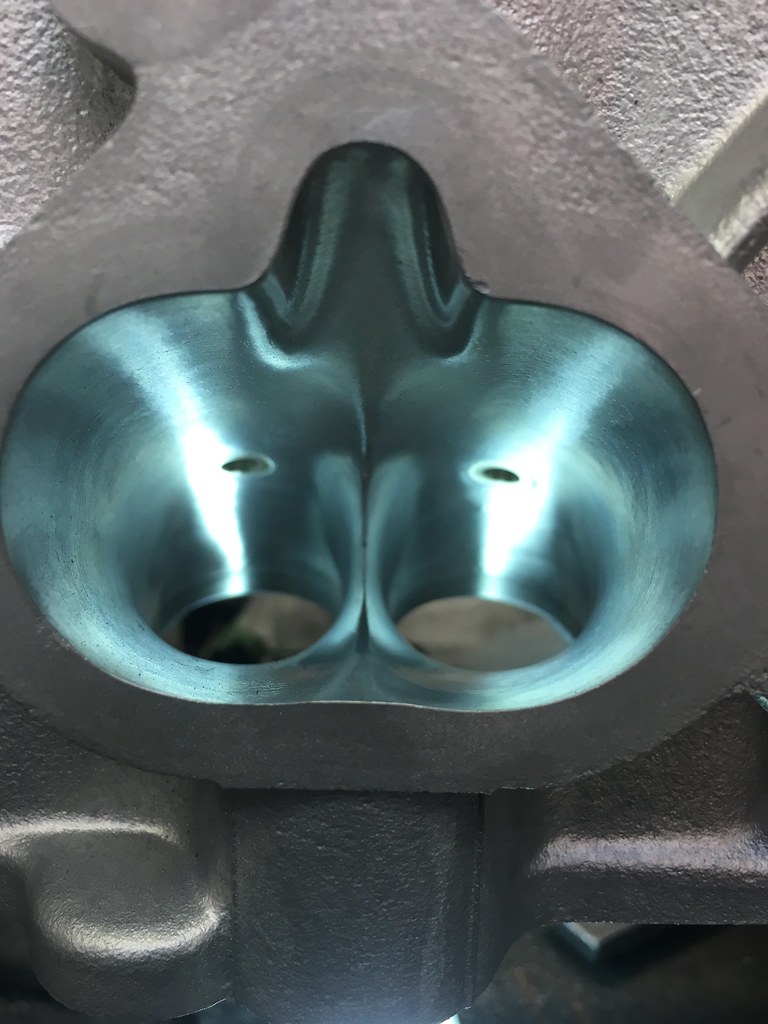

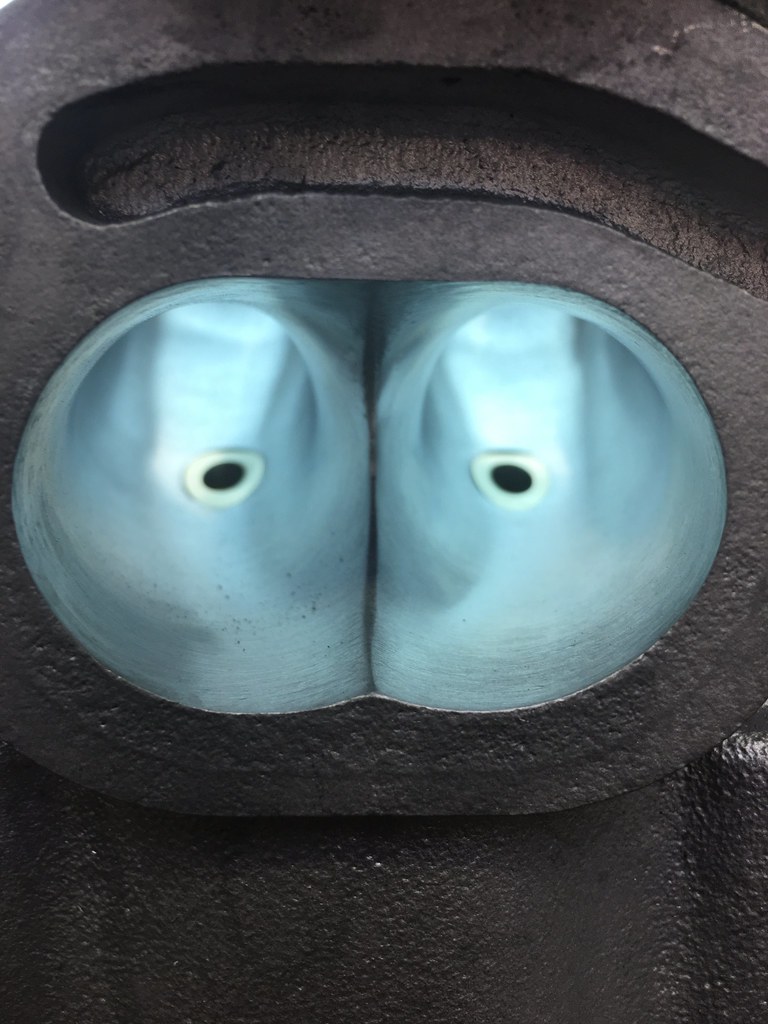

Short side radius is crap on these heads to the point where it would be more accurate to say that the a/f mixture skips across the back of the valve rather than makes the turn. Not entirely, but it illustrates a point. That limits the amount of valve curtain area the mix is trying to use, hampering flow. If you can help center the lot to be perpendicular to the back of the valve, it'll help flow, which I read to be the OP's goal.

Do rules prevent you from tigging this up?

Short side radius is crap on these heads to the point where it would be more accurate to say that the a/f mixture skips across the back of the valve rather than makes the turn. Not entirely, but it illustrates a point. That limits the amount of valve curtain area the mix is trying to use, hampering flow. If you can help center the lot to be perpendicular to the back of the valve, it'll help flow, which I read to be the OP's goal.

Do rules prevent you from tigging this up?

woodenpudden

lacks goats

- Joined

- Sep 27, 2005

- Location

- Princess Anne, MD

That the Norwegian guy? I can't recall his username if so, could you jog my memory?

flyfaen