The Backstory:

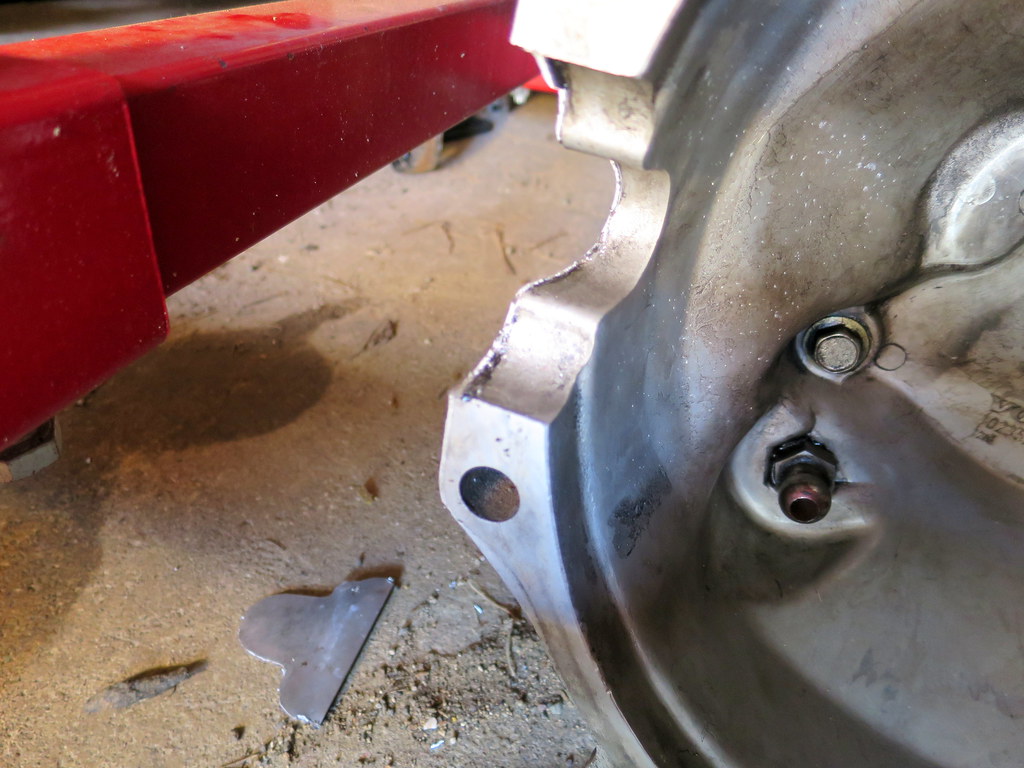

In February 2014 I saw an ad appear on Turborbircks for not one but two 1975 242s by 122power (aka Luke) located about an hour away in Fairfield, CA. The next day I was able to check them out and ended up buying one which was originally orange but had been repainted red by one of the previous owners. It had 110K on the odometer, was pretty solid and as expected with any used car some issues such as a cracked bellhousing, worn out shocks, strut bushings and other assorted things. The other car, an orange 242 was picked up by bigbret. During my test drive the orange car started loosing power and when getting to the parking lot couldn't really get above 15 mph.

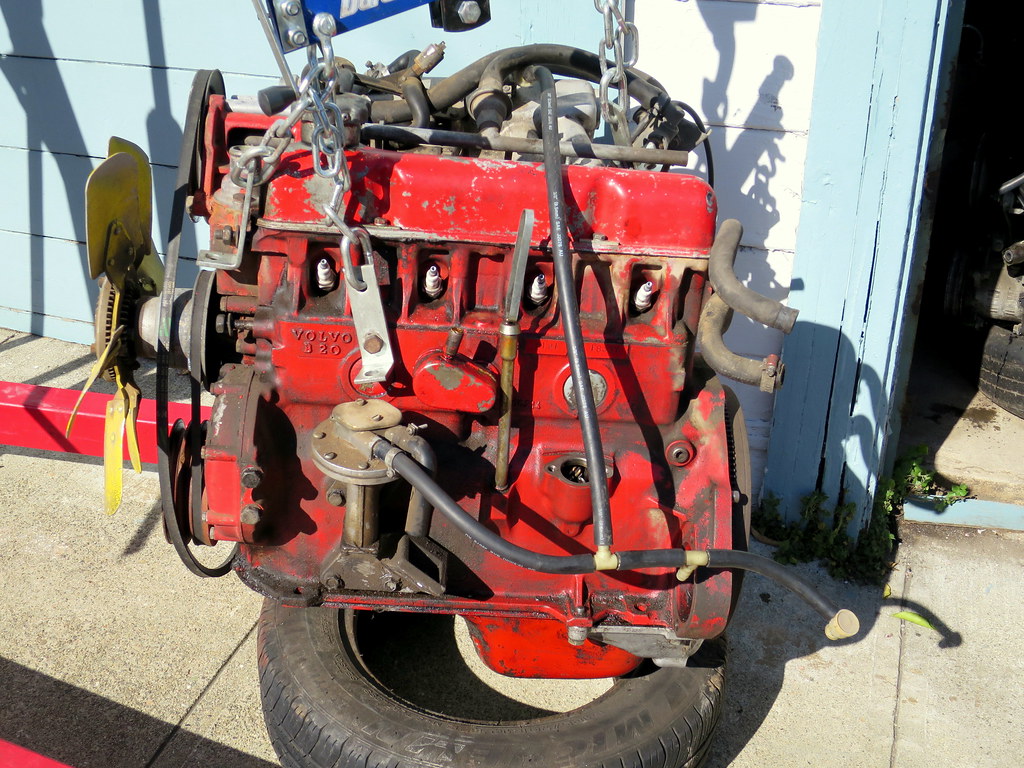

I had been searching for a first-year 242 for a while, already in my stable were a 1970 142S & 1973 142E. I do like the B20 engine, but prefer the B23/230 power plants. Converting a 142 to a OHC engine would be totally doable although a fair amount of work. Figured finding a 242 would make it easier in the long run even though here in California the 1975 models are hard to procure. The main reason I was looking to find a 75 is not so much because of the exempt status it has for smog testing, but around the year qualifications for the Northern California vintage car rallys. Some of these events (California Melee, etc.) require a 1975 or older vehicle in order to participate.

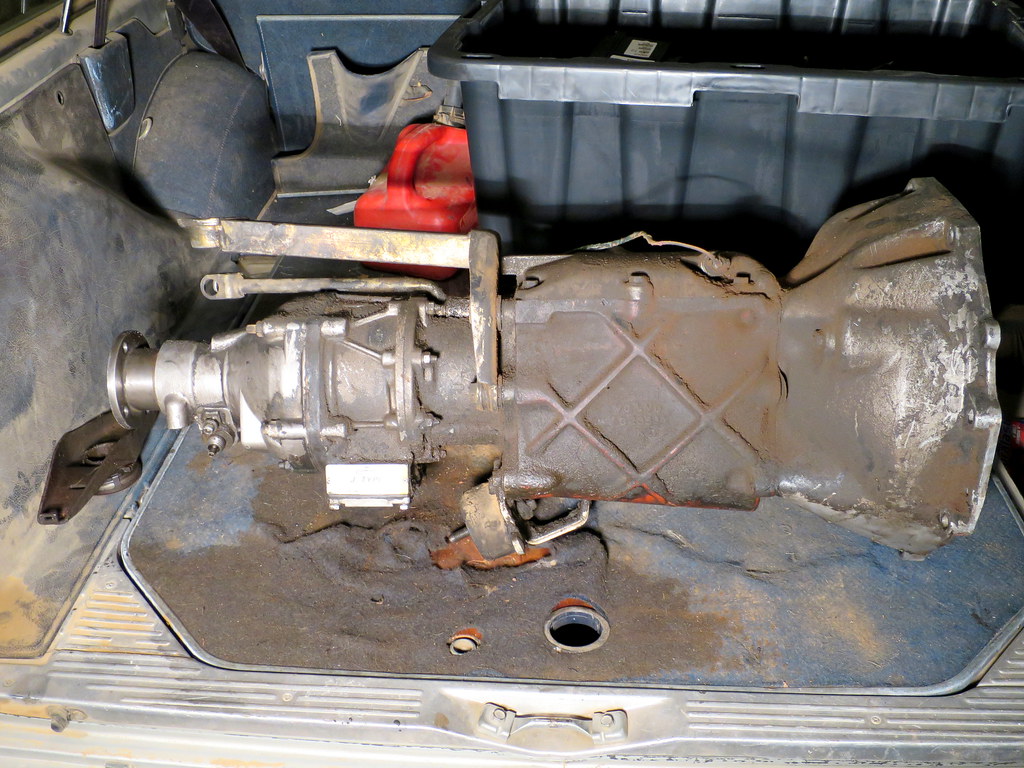

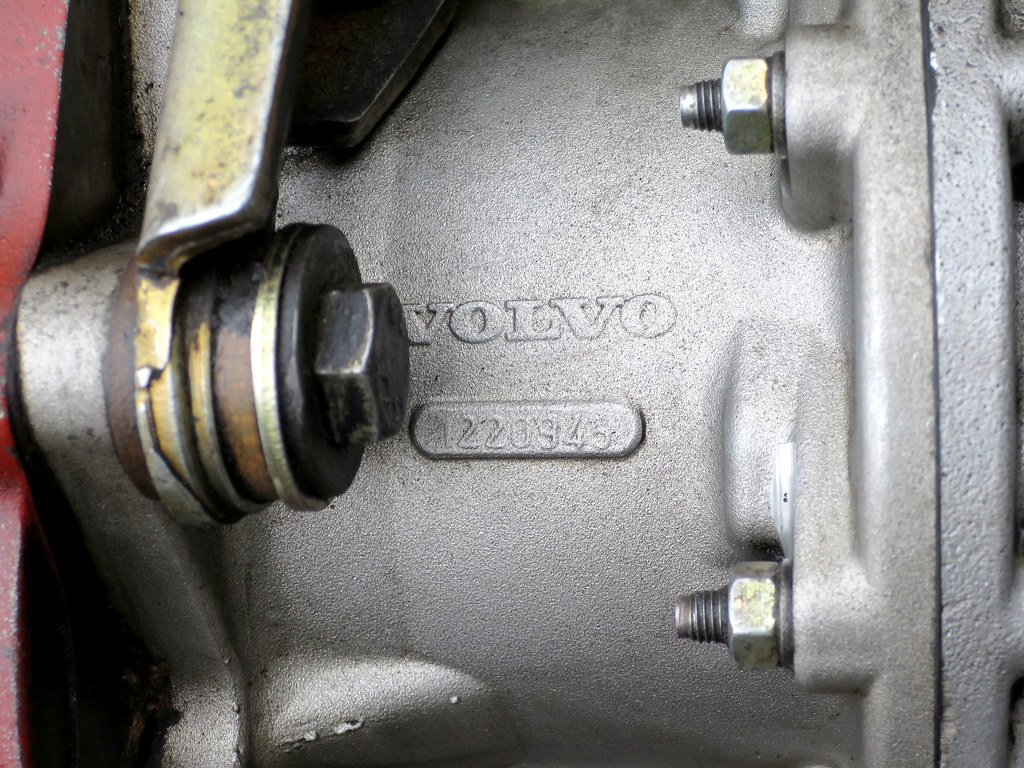

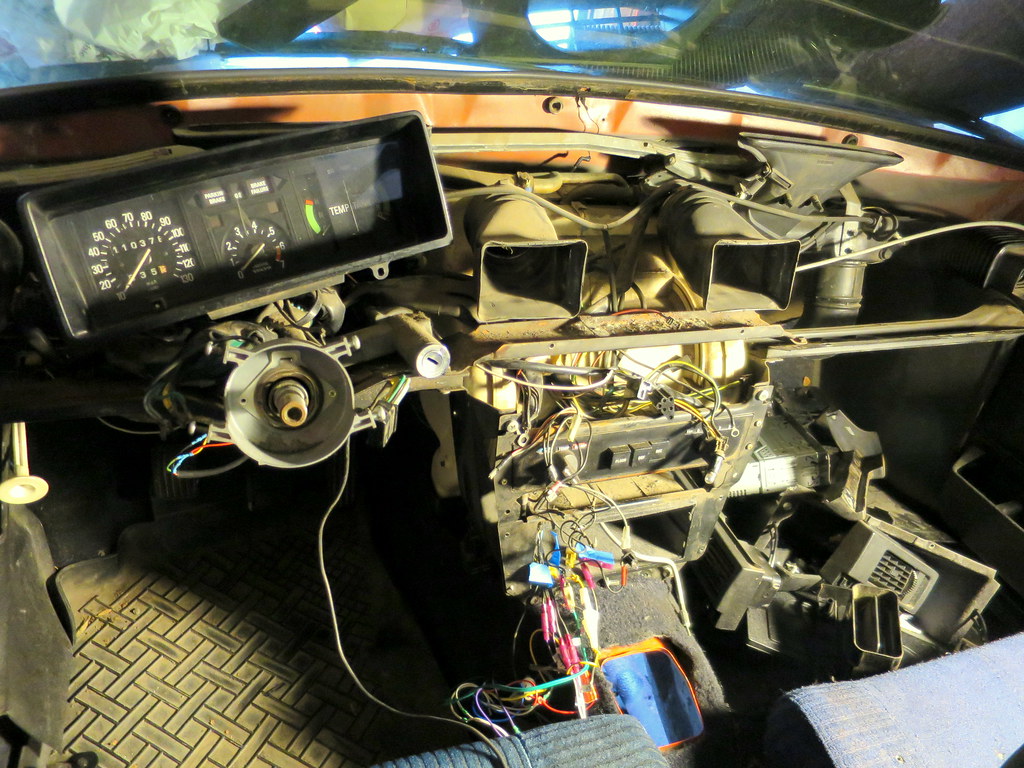

The next weekend I had the car flatbedded back to San Francisco. The next couple months was spend addressing the various issues on the 242. A new M40 bellhousing was sourced and that was installed onto the car. The ancient shocks were replaced out, new brake rotors installed, new rubber brake lines were put in as well as fbleeding the brakes with fresh, new brake fluid. In addition added an IPD 25mm swaybar up front to help tighten the suspension a bit. During a trip to the junkyard came across a 242DL and pulled out the passenger front seat and rear bench seat. These seats were originally destine for the 1970 142S but decided to take the black interior out of the 242 and put that into the 142S instead.

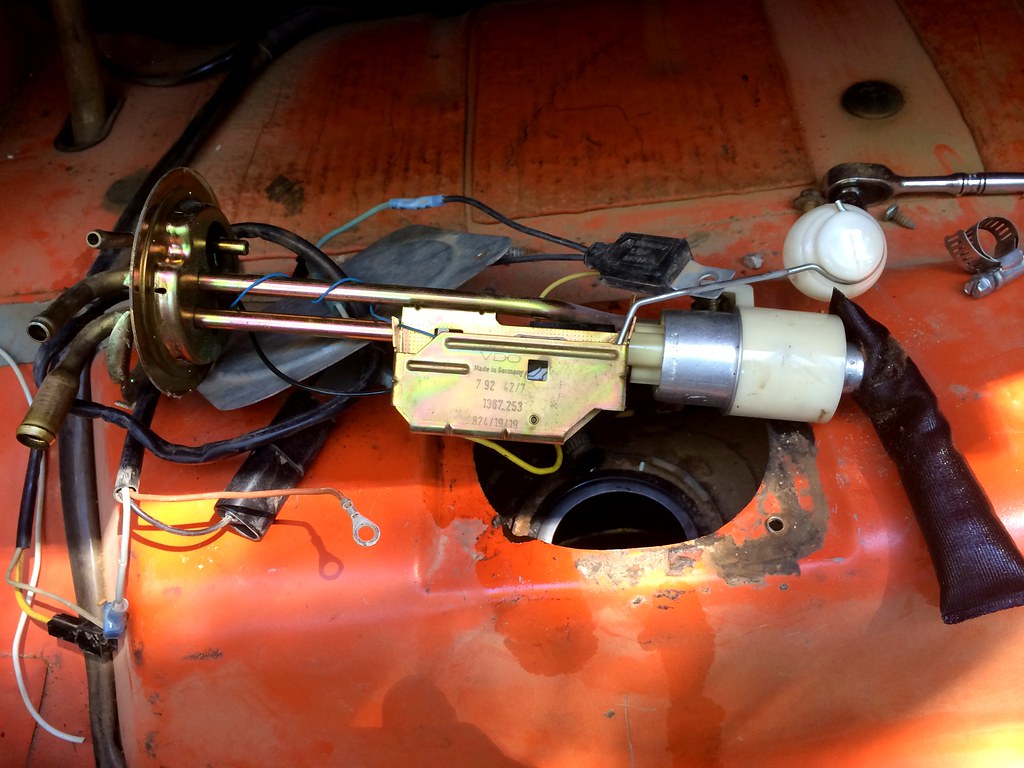

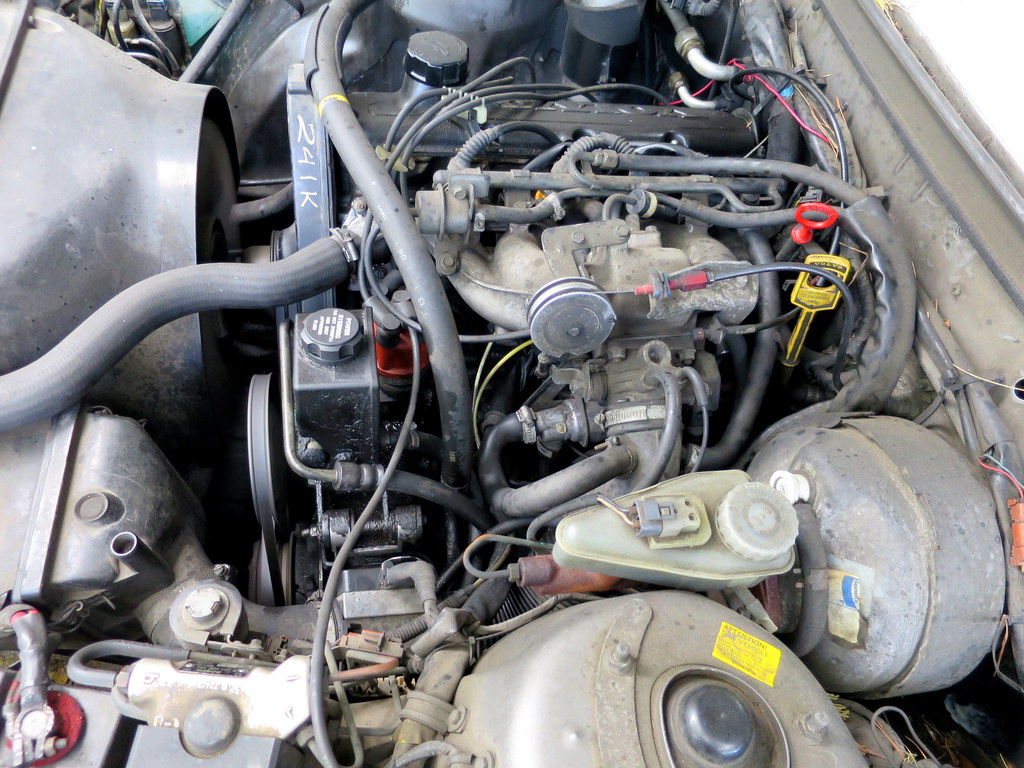

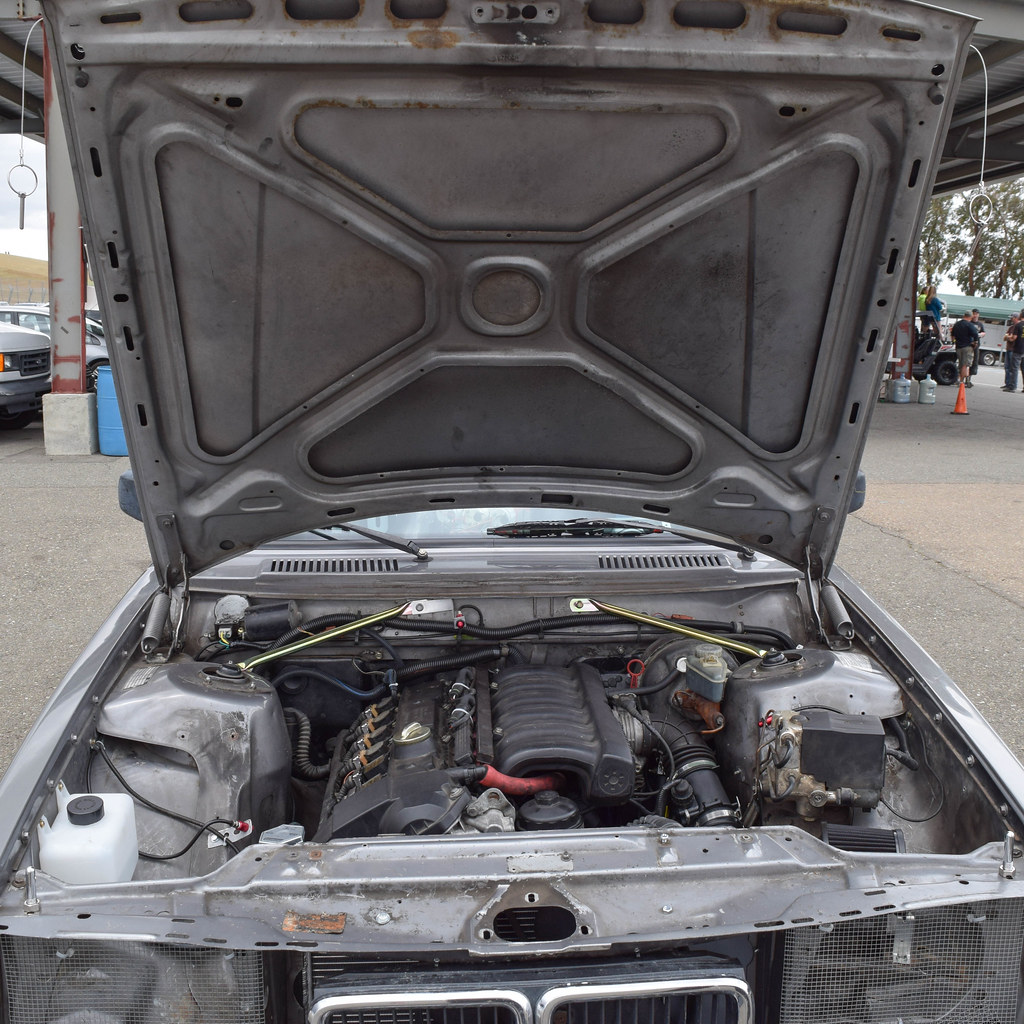

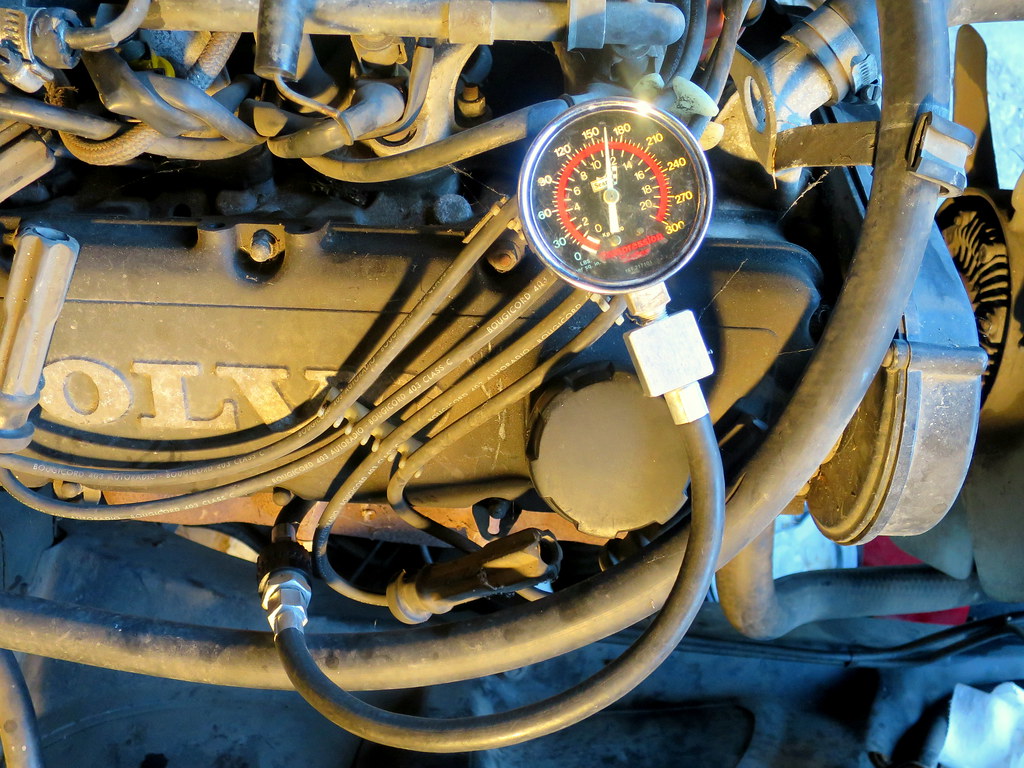

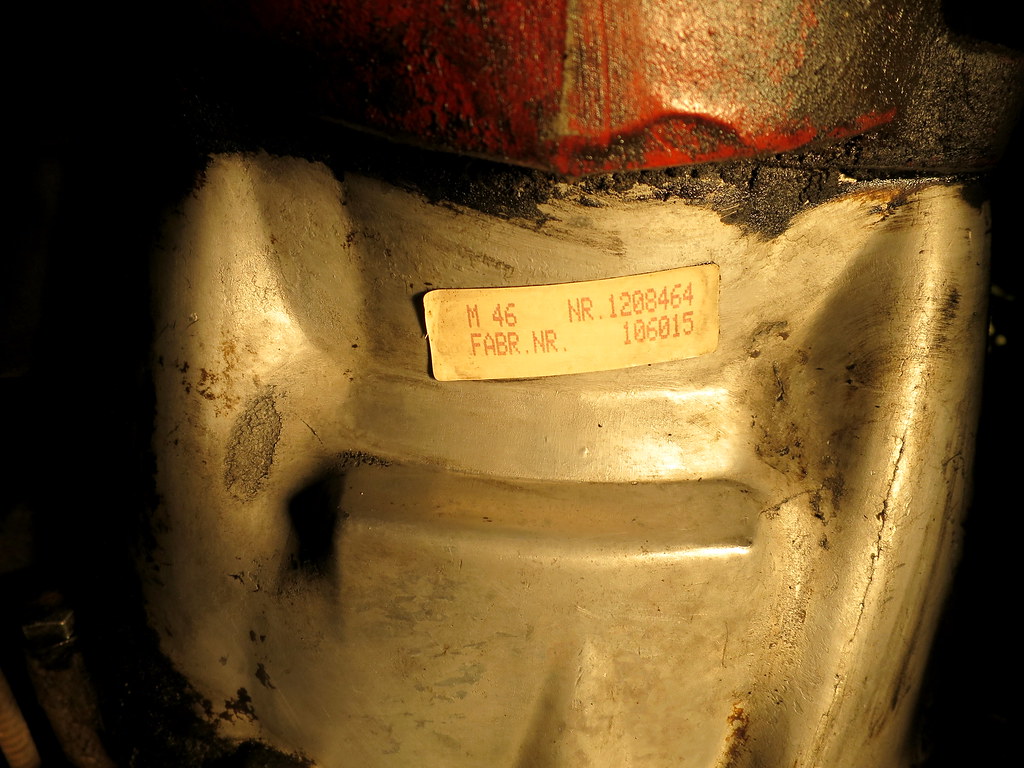

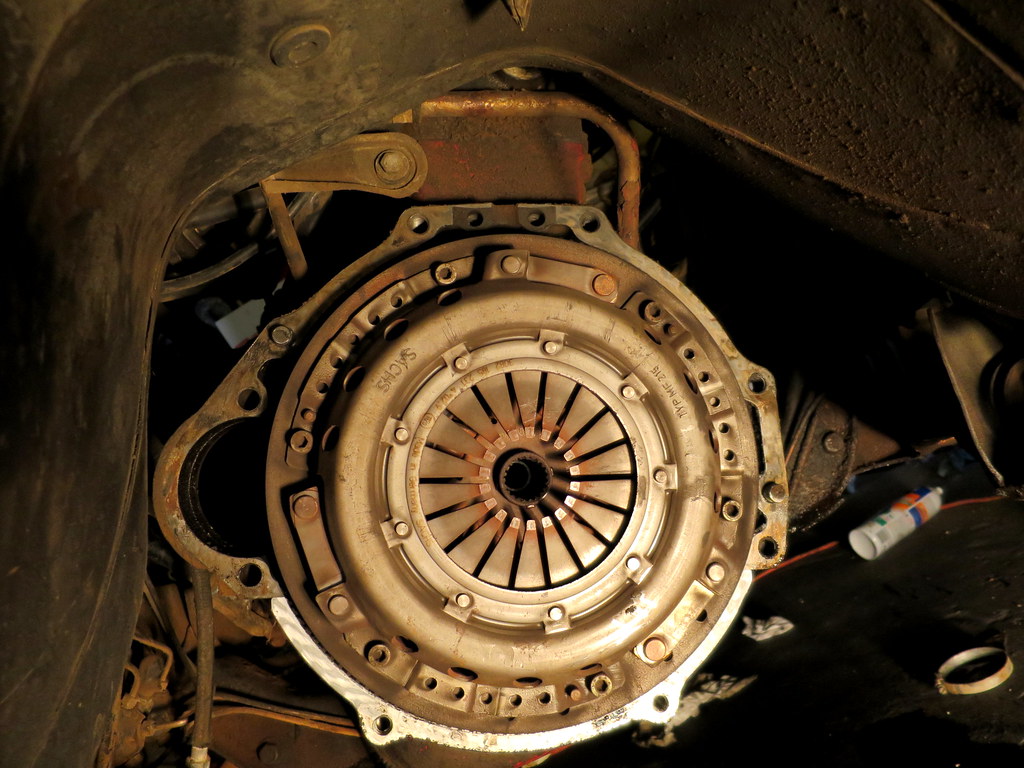

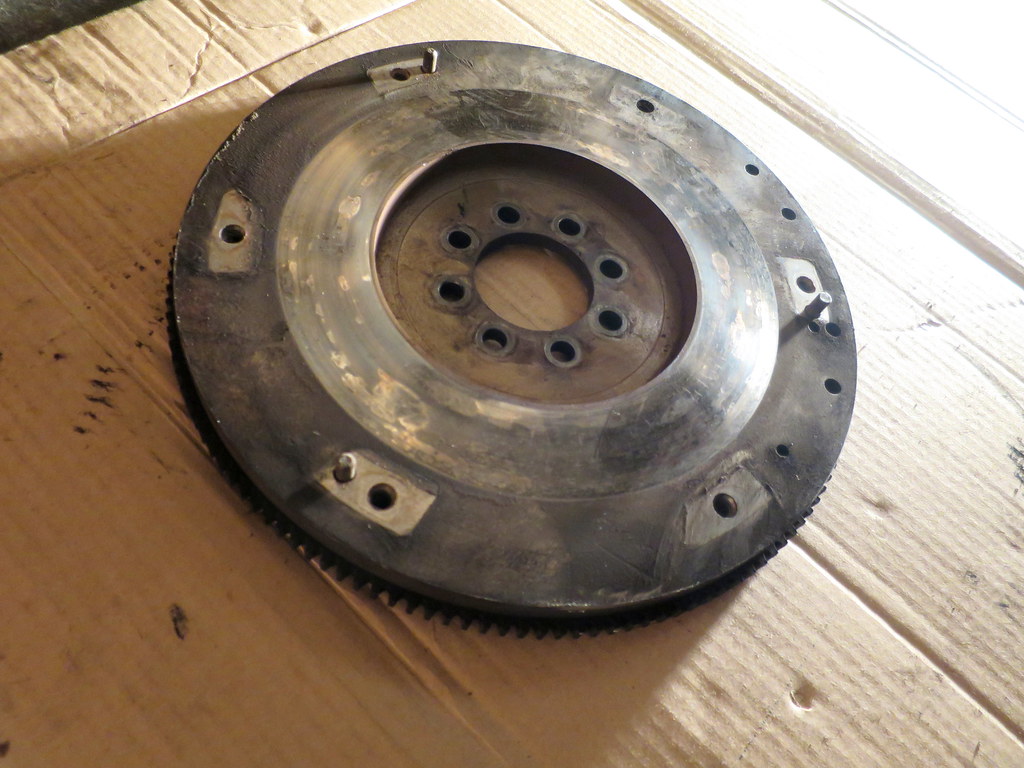

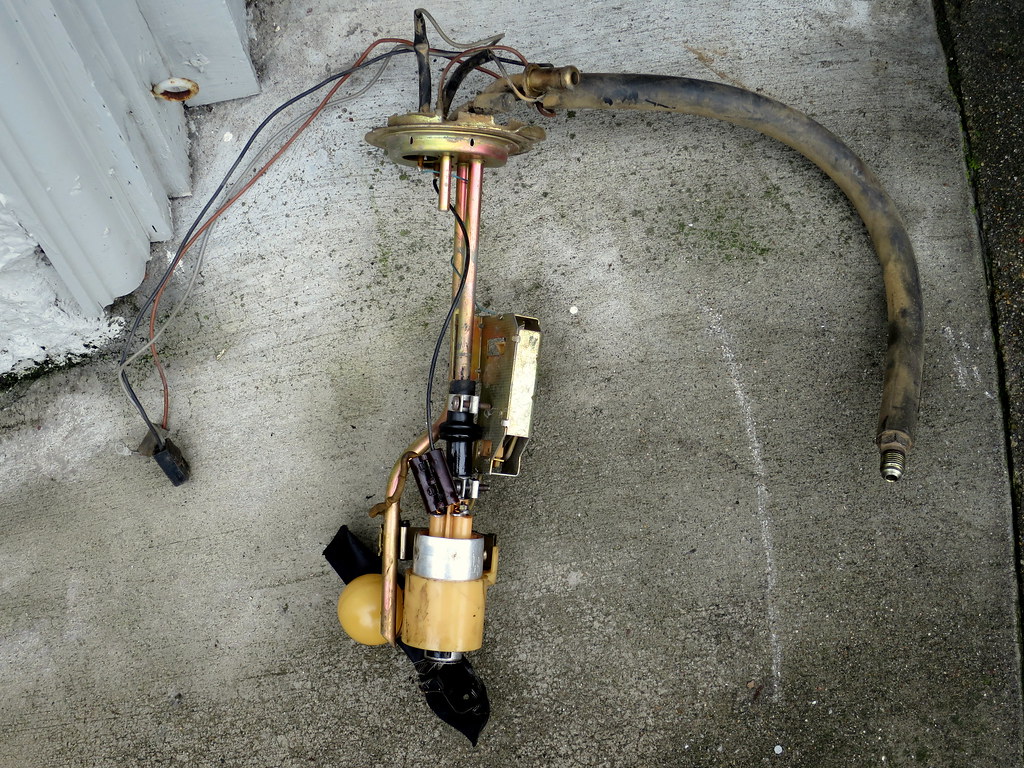

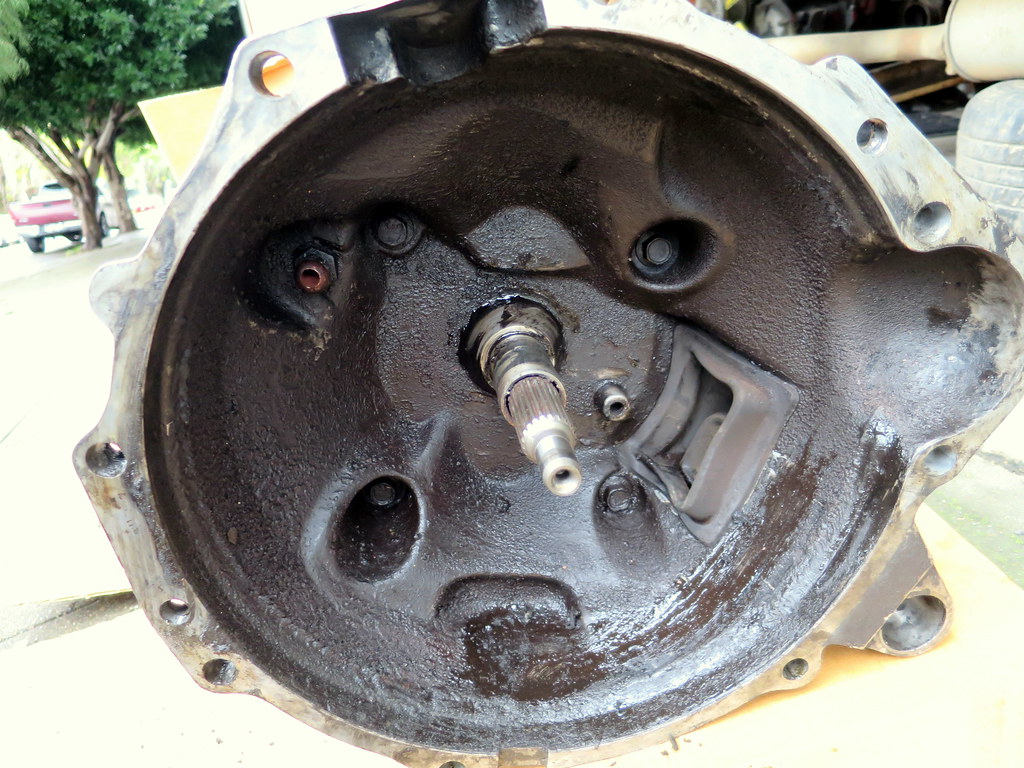

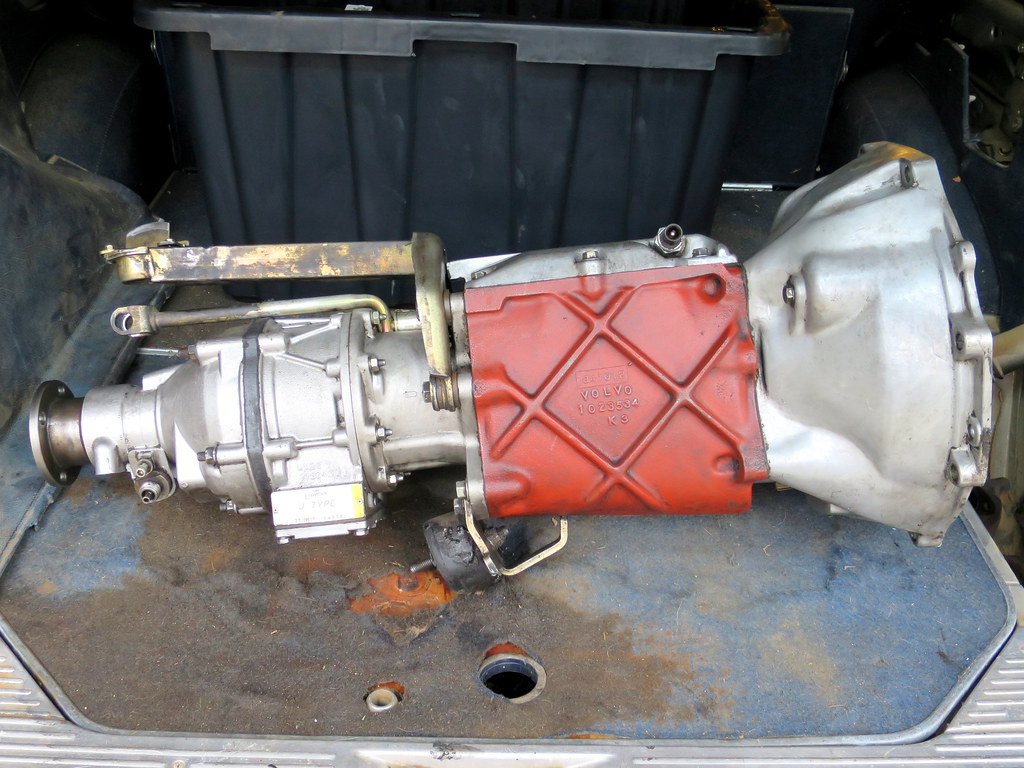

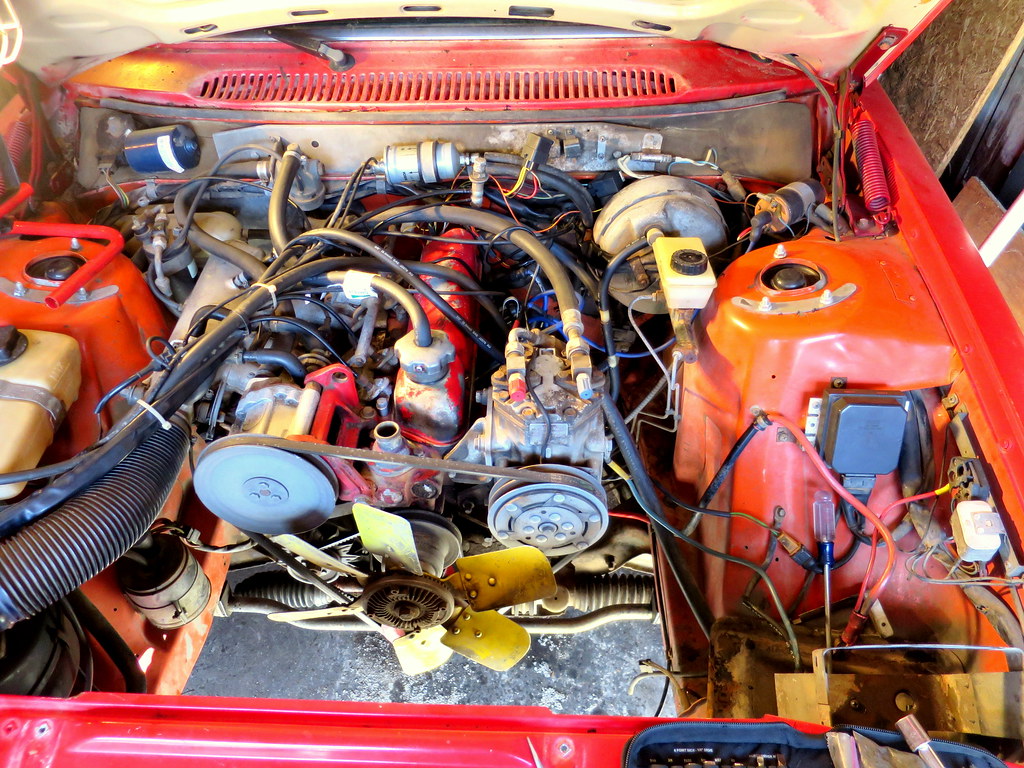

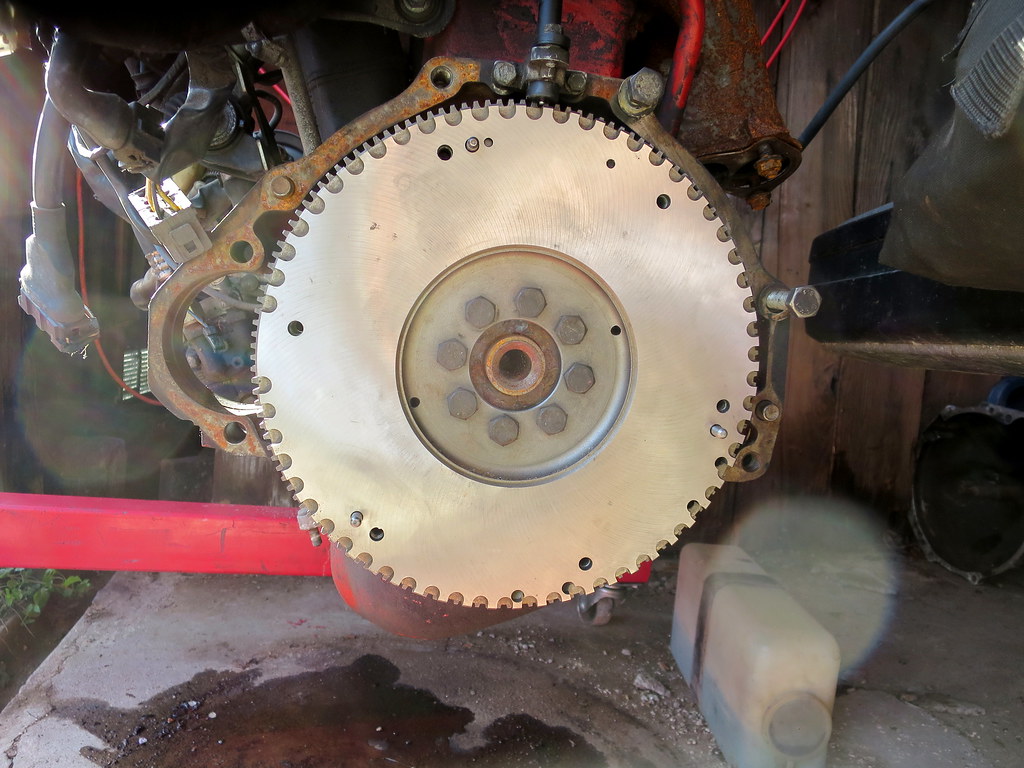

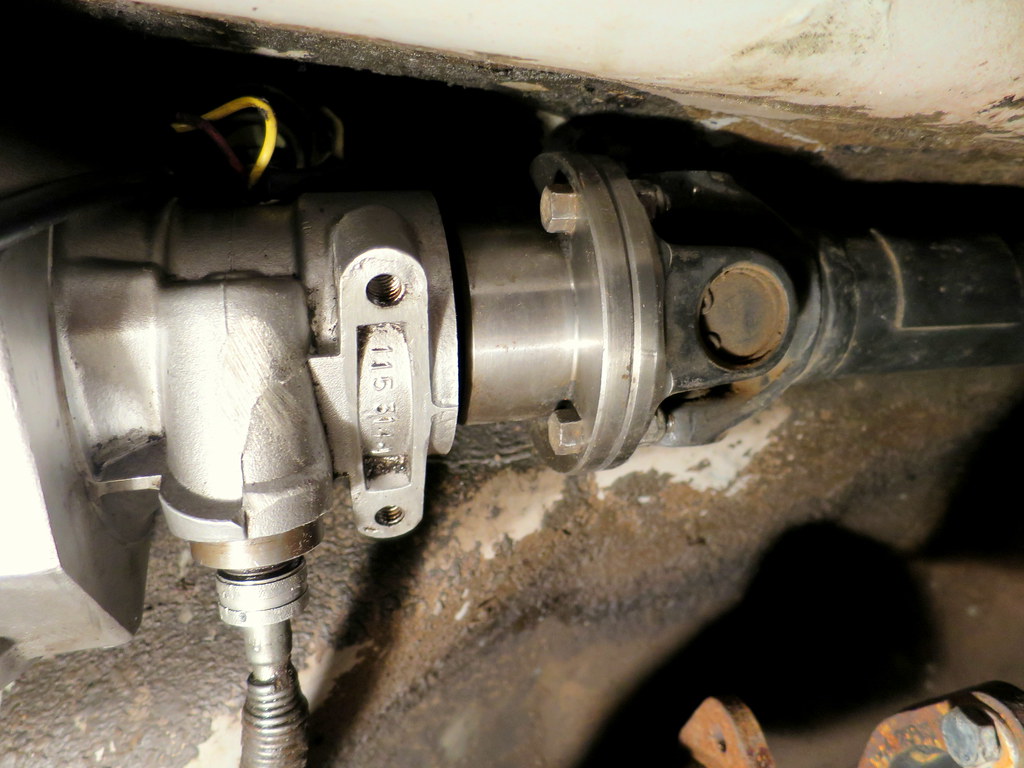

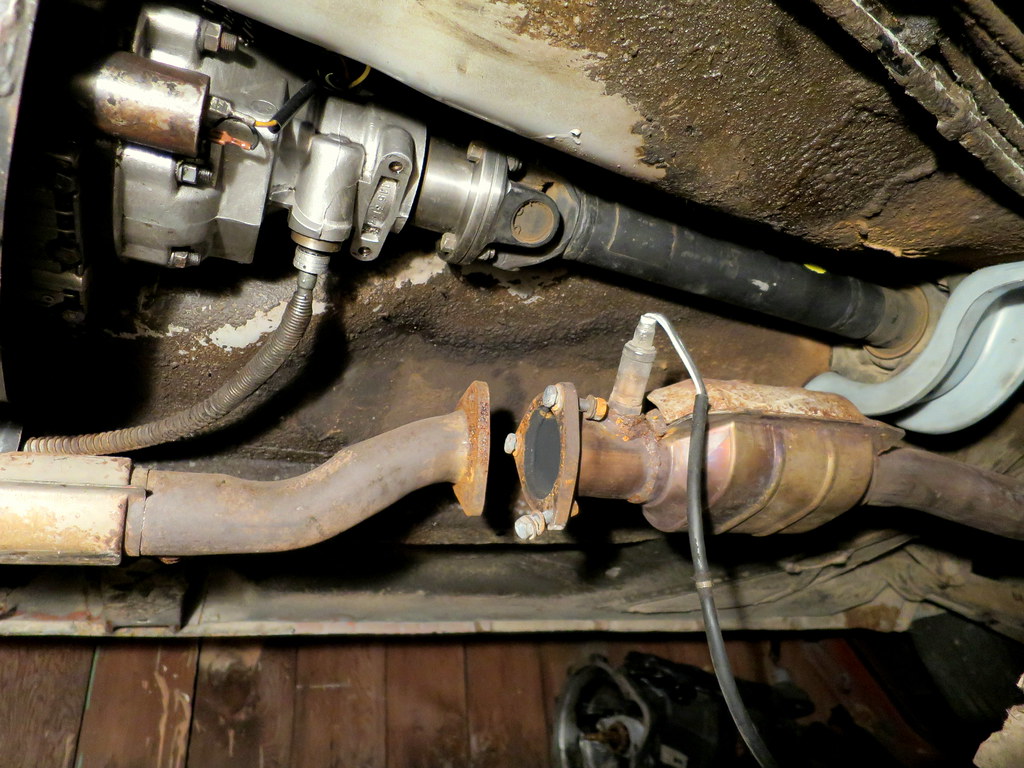

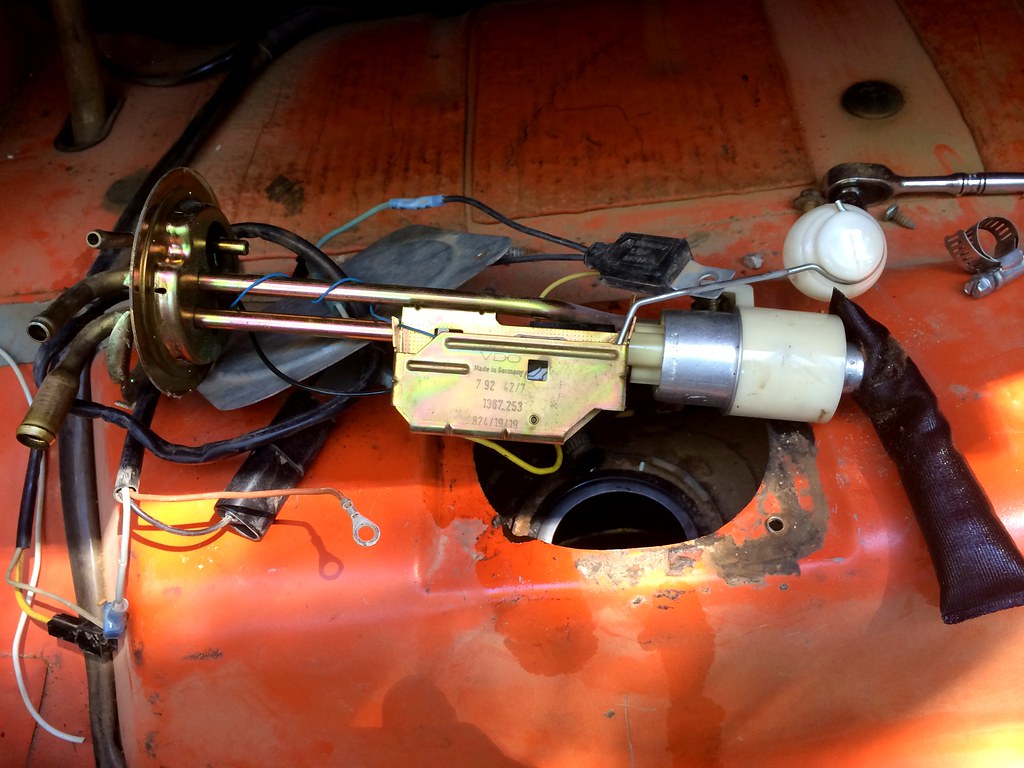

During the summer, the fuel injection system was really acting up. When cold the car would barely start as it seemed to be initially running on one cylinder. Keeping it running was quite the chore and slowly it would smooth out. Only after about 5-7 minutes would it be ok (aka warmed up) enough to be able to drive. The contemptuous nature of the car relegated it into the garage rather than a dependable daily driver. Additionally not a fan of the K-jet fuel injection system so I while I figured the issue was most likely the fuel pressure regulator, I really didn't want to dig into that much. The plan since acquiring the 242 was to upgrade the powertrain to something in B23/230 family with a Lh FI system and a M46 transmission so needed to concentrate on that.

In February 2014 I saw an ad appear on Turborbircks for not one but two 1975 242s by 122power (aka Luke) located about an hour away in Fairfield, CA. The next day I was able to check them out and ended up buying one which was originally orange but had been repainted red by one of the previous owners. It had 110K on the odometer, was pretty solid and as expected with any used car some issues such as a cracked bellhousing, worn out shocks, strut bushings and other assorted things. The other car, an orange 242 was picked up by bigbret. During my test drive the orange car started loosing power and when getting to the parking lot couldn't really get above 15 mph.

I had been searching for a first-year 242 for a while, already in my stable were a 1970 142S & 1973 142E. I do like the B20 engine, but prefer the B23/230 power plants. Converting a 142 to a OHC engine would be totally doable although a fair amount of work. Figured finding a 242 would make it easier in the long run even though here in California the 1975 models are hard to procure. The main reason I was looking to find a 75 is not so much because of the exempt status it has for smog testing, but around the year qualifications for the Northern California vintage car rallys. Some of these events (California Melee, etc.) require a 1975 or older vehicle in order to participate.

The next weekend I had the car flatbedded back to San Francisco. The next couple months was spend addressing the various issues on the 242. A new M40 bellhousing was sourced and that was installed onto the car. The ancient shocks were replaced out, new brake rotors installed, new rubber brake lines were put in as well as fbleeding the brakes with fresh, new brake fluid. In addition added an IPD 25mm swaybar up front to help tighten the suspension a bit. During a trip to the junkyard came across a 242DL and pulled out the passenger front seat and rear bench seat. These seats were originally destine for the 1970 142S but decided to take the black interior out of the 242 and put that into the 142S instead.

During the summer, the fuel injection system was really acting up. When cold the car would barely start as it seemed to be initially running on one cylinder. Keeping it running was quite the chore and slowly it would smooth out. Only after about 5-7 minutes would it be ok (aka warmed up) enough to be able to drive. The contemptuous nature of the car relegated it into the garage rather than a dependable daily driver. Additionally not a fan of the K-jet fuel injection system so I while I figured the issue was most likely the fuel pressure regulator, I really didn't want to dig into that much. The plan since acquiring the 242 was to upgrade the powertrain to something in B23/230 family with a Lh FI system and a M46 transmission so needed to concentrate on that.