My deadline to finish the "91 245 was Christmas. Delving into the rear axle has f-up'd my schedule. But everything takes me 2 to 3x as long as it should anyway.

I've read the threads on the rear drive swaps...but too many off them were read after I ripped it all apart.

Two questions:

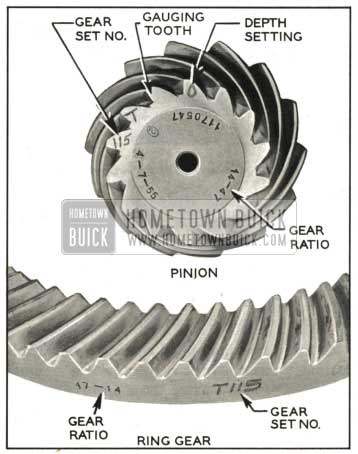

1) I believe this swap is fine without changing the pinion? Its a 1991 245 open Diff wagon getting a 1993 244 (Seden) LSD? Just swap them right? I already made the mistake of having no idea how deep the pinion nut was.

2) As you'll see the second photo, the pinion seal was a PITA to get out. The PO had red thread locker or something on the seal where it mates to the inner pinion shaft. That is totally unnecessary correct?

I also welcome any other advice or comments, before I put it back together.

I've read the threads on the rear drive swaps...but too many off them were read after I ripped it all apart.

Two questions:

1) I believe this swap is fine without changing the pinion? Its a 1991 245 open Diff wagon getting a 1993 244 (Seden) LSD? Just swap them right? I already made the mistake of having no idea how deep the pinion nut was.

2) As you'll see the second photo, the pinion seal was a PITA to get out. The PO had red thread locker or something on the seal where it mates to the inner pinion shaft. That is totally unnecessary correct?

I also welcome any other advice or comments, before I put it back together.