hiperfauto

The Librarian

- Joined

- Nov 18, 2011

- Location

- So Cal

Be careful when removing the case half bolts. Type 30 Powr-Loks have left hand thread bolts. I'm not sure what the Type 27 uses and the manual makes no mention of it.

Hello Guest, welcome to the initial stages of our new platform!

You can find some additional information about where we are in the process of migrating the board and setting up our new software here

Thank you for being a part of our community!

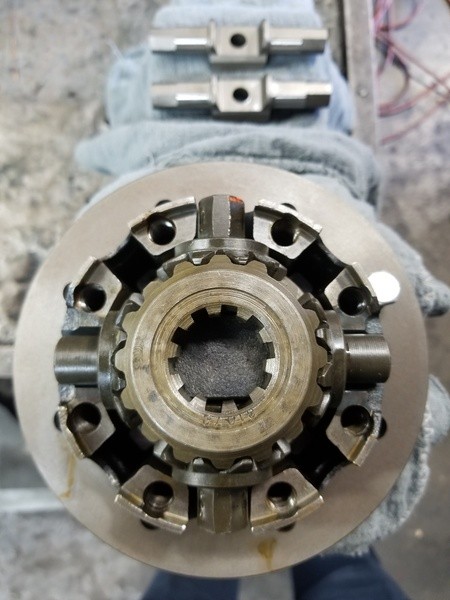

Watching this.....just cracked open my Dana 27 rear cover as part of a rebuild and found a powr-lok installed dated 1973 and it still looks brand new......but moving the vehicle into the side yard before Christmas in the snow revealed a spinning rear right tire, so I guess I need new clutch packs. Only place I've seen is Herm the overdrive guy. Are his parts NOS or are they new manufacture?

Please post pics of your disassembly and advise if the bolts are left or right hand threaded!

Patrick

PS mine is a 42 GPW and not an early 60s Amazon.

Big bump on this, as I'm looking for info on the cross shafts.There is one hitch though. These were destined for front axles in Jeeps and therefore lack the proper internal cross shafts and axle centering pins that are required when installed in a Volvo rear differential with drum brakes.

See parts 7-9 on your VP Autoparts website:

http://212.247.61.152/us/main.aspx?page=article&artno=1201060520

There is a solution to this though as another supplier has now came in to reproduce the proper cross shafts and centering pins.

http://hermtheoverdriveguy.com/d232527-powerlock-cross-shafts

I would also use this page in reference to reassembly or overhaul of these units when performing this needed operation as well as the supplemental Green Book:

https://cj3b.info/Tech/SB500PowrLok.html

More great reference material here:

https://people.physics.anu.edu.au/~amh110/Diff_LSD/diff_lsd_volvo_dana.htm

Awesome, thank you for the clarification. That it exactly what I was thinking as well.The centering pin is required on all rear ends with 2 piece axle bearing/race (544/122/1800 -'69) and early 140's. These rear ends need to have the axle bearing end play shimmed (or adjusted in the case of early 140's) and the ends of the axles need to butt against each other through the centering pin or spacer in the diff. Later rear ends use an axle bearing assembly that's not adjustable and therefore don't need the centering pin/spacer.