A thing to note, you will likely not want to run MORE ignition timing than factory with whatever you end up doing(assuming thinner headgasket and higher compression).

Regarding the exhaust, ideally you'd replace the full system with the downpipe's 2-1 merge being redone to exit in a 2.25" or 2.5" pipe and continue that diameter all the way back. Not just installing IPD's "performance" 2.25" cat back exhaust has the disgusting crush underneath the axle.

Your injectors will probably be fine for now, but ideally the white bodied ones from the 16V motor will be right in their happy operating range if you switched to those instead. I don't know how LH2.2 will manage with them, though.

For port work, like mentioned above, there's no need to do port matching(gasket mating area), you don't want to create a bubble in the flow. You DO want to make sure the flow isn't running into any walls, though, so you could gasket match the inlet of the exhaust manifold if you want, or check to see it's necessary before bothering.

That being said, it is worth at least making sure the ports are clean and smooth with no rough edges. Like Shoestring mentioned, you won't get much power or peak flow, but my opinion is that every bit counts. Erland Cox recommended on our General Leif 405 head we

remove the sharp edges under the exhaust valve seat and the exhaust short turn. On the intake side, it's usually good but you can blend the machined areas under the valve with the cast port.

If you are putting in larger valves, you need to open up the seats and ports to accommodate them. I'm not sure where your napkin math is coming from, but it's not that simple that you are going to get 6hp from putting in larger valves.

You're overthinking this low end torque thing. No factory cam is going to kill that to the extent you mention in your first post(gutless under 3k), unless you're going to an aftermarket camshaft designed more for racing. The K cam is not designed for racing and will have plenty of power at low rpm with the associated increased static compression. If you want it to idle like stock and maybe have similar peak power, get the ENEM V15 camshaft. The IPD Turbo camshaft will work as well, but won't make quite as much peak power because it has a higher lobe separation angle to work better with turbo cars. Is it a noticeable difference? I don't know. The factory A cam performed just as well as the IPD turbo cam when my NLMGG was basically stock. That may or may not have been due to the rest of the car's setup at the time, and/or the dyno.

I just want to point out again, that the 531 head has larger intake ports with lower velocity that will make it be less responsive and have less torque than the same setup(assuming a smaller factory camshaft, like the V) with a 530 head. The benefit of that larger intake port comes to play when you get to and over 12mm of lift.

http://forums.turbobricks.com/showthread.php?t=232036

Flow sheets, yes, please!

http://forums.turbobricks.com/showthread.php?t=329718

I'll second that you will want to build up the 1993 motor. Why not? Just because it wasn't running well doesn't mean that it's the engine's fault. If you are to rebuild a bottom end, build the 1993 so it lasts longer. You can put the 531 head on either, including using it on the current '86 block for now, while you one day rebuild the '93 block to swap it over at another time. Maybe at that time, you'll also want to do something different than you will with this first go around.

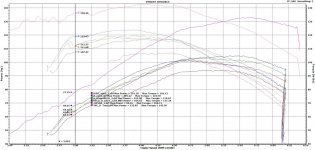

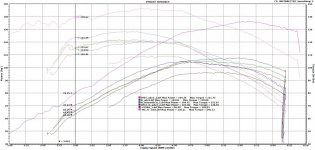

DYNO RUNS BELOW:

I have dyno runs of the A cam, the V15 NA cam, the D cam, the RSI Stage 1 and B cam when my NLMGG 244's engine was unopened, but they're all with an automatic, varying levels of intake airbox modification, varying exhaust system modifications(cat-back 2.5", not sure when I did it), not all on the same day and not all on the same dyno. See attached, including one run after a manual transmission swap, header(unnecessary,) H cam, a mildly ported, 46/38mm valved 530 head with .040" off and a .040" headgasket(Cometic MLS) for fun. I changed the scale of these dyno plots so you can try and make out the different runs easier. In reality, the differences are not that great! The first chart is with SAE correction turned on to in theory make them comparable runs, the second chart is uncorrected values.