Any six cylinder t6 experts on here?

Just wondering what component parts make the best t6 engine for my 240 project?

Thoughts so far are.....

1998 T6 block, rods and pistons.

1998 s90 sump, oil pick up and other bits to make it mount the correct way.

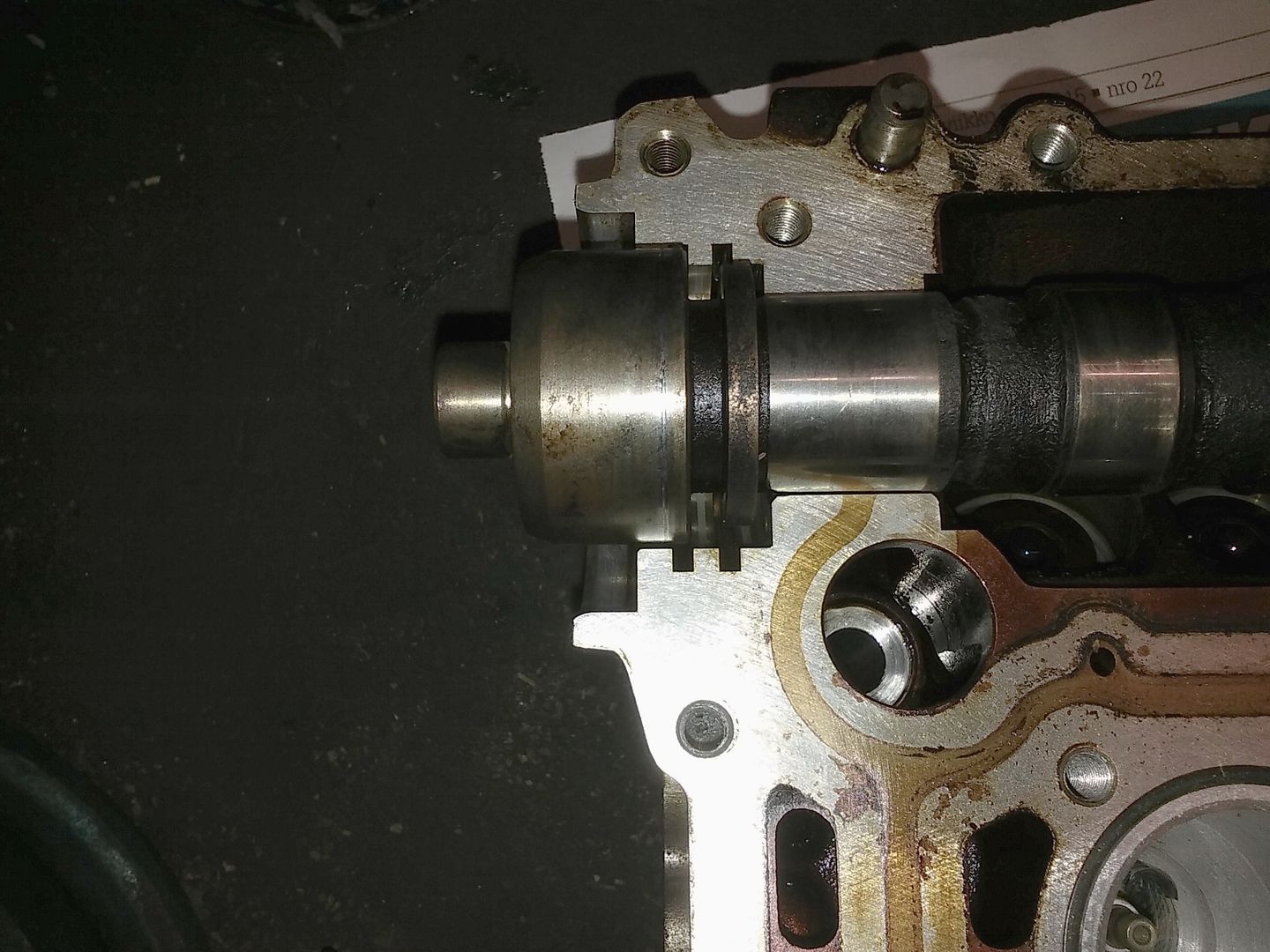

S90 cylinder head with cams to remove the variable exhaust valve timing fron the t6.

Bmw turbo manifold with flange modified.

S90 intake stubs with custom plenum.

850r clutch with whiteblock m90 gearbox.

Stand-alone management with clocks (not sure which).

Front sway bar?

Obviously all the niff-naff with intercooler, radiator etc, etc but that's easy enough. It's advice on the Volvo specific bits I'm really interested in.

Sorry if this is a bit noddy, but I'm more of a VW man so Volvos are new to me.

Oh, anyone got a link for an engine manual for torques and the like?

Cheers for any input and ideas.

Just wondering what component parts make the best t6 engine for my 240 project?

Thoughts so far are.....

1998 T6 block, rods and pistons.

1998 s90 sump, oil pick up and other bits to make it mount the correct way.

S90 cylinder head with cams to remove the variable exhaust valve timing fron the t6.

Bmw turbo manifold with flange modified.

S90 intake stubs with custom plenum.

850r clutch with whiteblock m90 gearbox.

Stand-alone management with clocks (not sure which).

Front sway bar?

Obviously all the niff-naff with intercooler, radiator etc, etc but that's easy enough. It's advice on the Volvo specific bits I'm really interested in.

Sorry if this is a bit noddy, but I'm more of a VW man so Volvos are new to me.

Oh, anyone got a link for an engine manual for torques and the like?

Cheers for any input and ideas.