IansPlatinum

Active member

- Joined

- Jul 23, 2018

- Location

- Texas

A few puzzling things have cropped up:

The most puzzling involves gas. About a month ago I topped up the fuel tank. I didn?’t need to but I wanted to benchmark my fuel gauge and usage. It spit out violently when it told me it was full. No problem. I parked it for a week and discovered a puddle under the tank. Fuel was leaking from the fuel sender gasket. An easy fix...I thought. When I received the rubber gasket from VP, I drove around a lot to get the fuel level down enough to change the gasket. The old cork gasket was split so I installed the new one and snugged it down tight. So why is it still sweating gas around the sender? I cleaned it up again and tightened it but it still does it. I removed the charcoal canister up front and was careful not to plug up the hose end in case it is a tank pressure thing. When I remove the gas cap, there isn?’t any ?“whoosh?” sound. Lastly, I?’m down probably 3 or 4 gallons from full.

I had a similar issue on my 71. The sender doesn't ever hit a stop when it seals, it'll just unseal again if you keep turning it. I didn't realize this, because other senders I'd installed had a stopping point that would prevent further turning of the sender unit once it was fully installed.

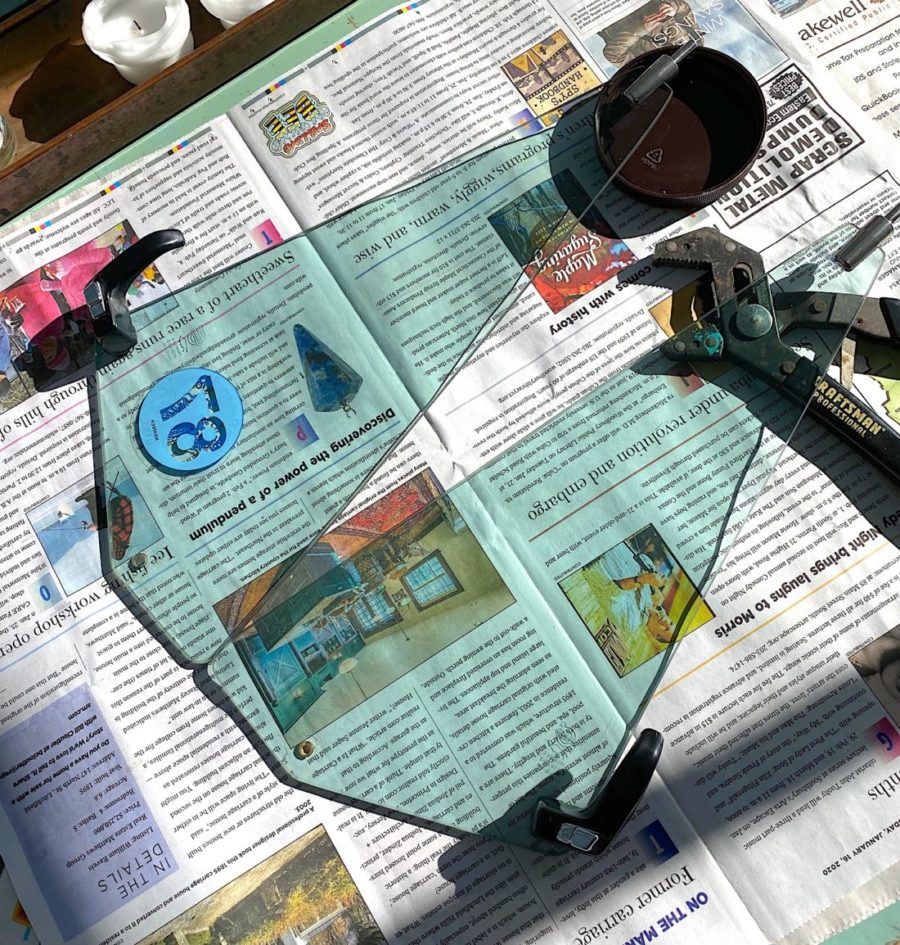

There should be 6 lobes on your sender that will bite onto 6 tangs present on the hole at the top of your gas tank. I'd remove the sender & make sure each tang is level with the rest of the sheet metal of the gas tank. If necessary, maybe gently bend them down with a soft piece of wood.

Then, this part will be hard to describe, but maybe you'll get the hang of what I'm trying to say... There should be 6 lobes on the sender. So, every 60 degrees of turning during installation will set you right back to where you started. Therefore, you need to install the sender by placing it in the hole of the tank and then turn it exactly 30 degrees.

I'd maybe take a sharpie and mark a zero on the sender & tank with the sender placed in the hole, then remove sender & use a protractor to mark 30 degrees of rotation onto the tank. Then reinsert the sender, and turn it until the previously made mark lines up with the 30 degree mark on the tank.

If you look at my build thread, I had the exact same problem. I over-rotated the sender during install to where it was still seated but not sealed.